Yooheart Robotic Palletizing System, Bag Palletizer Machine, Palletizing Robot

Production Introduction

The core parts of Yooheart palletizing robot

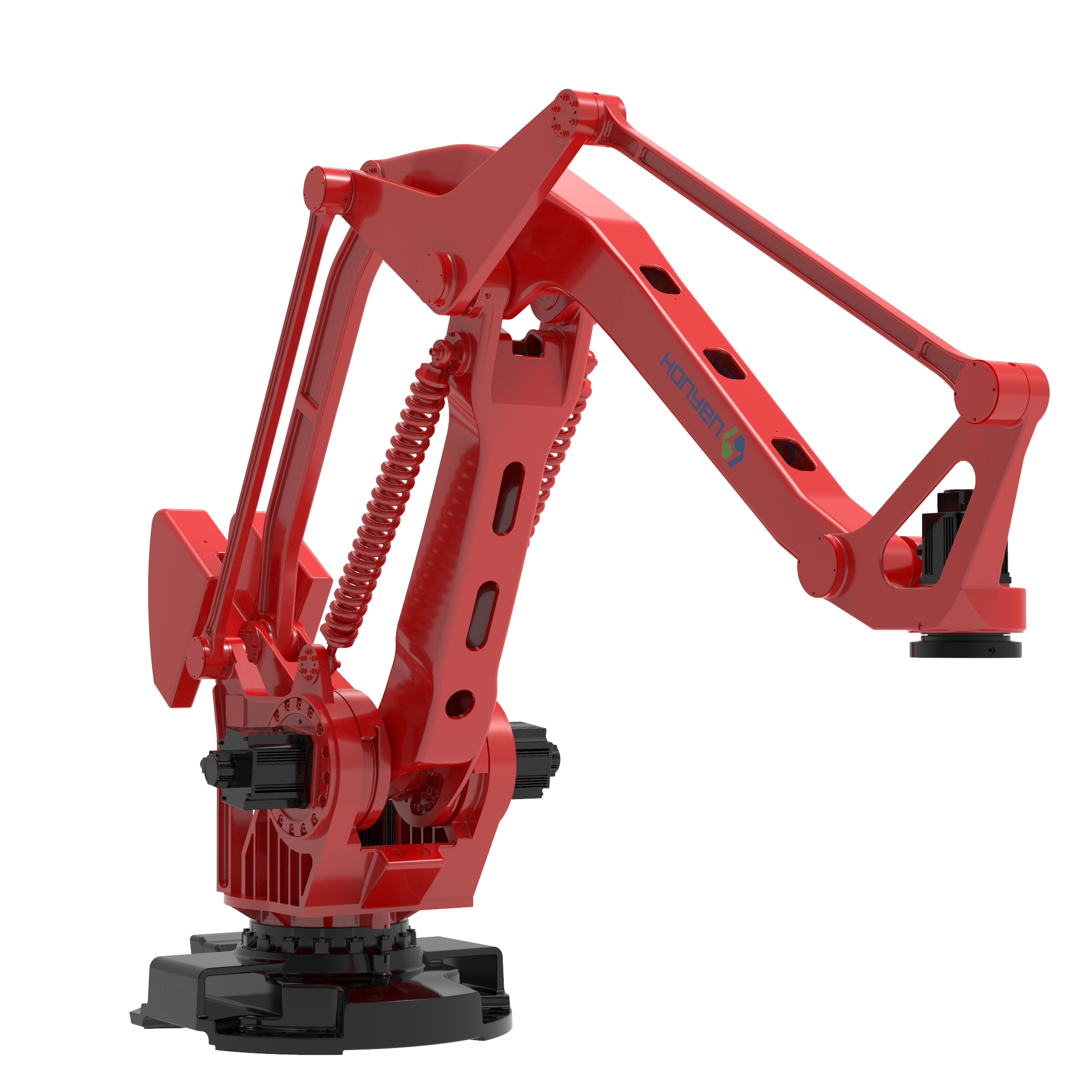

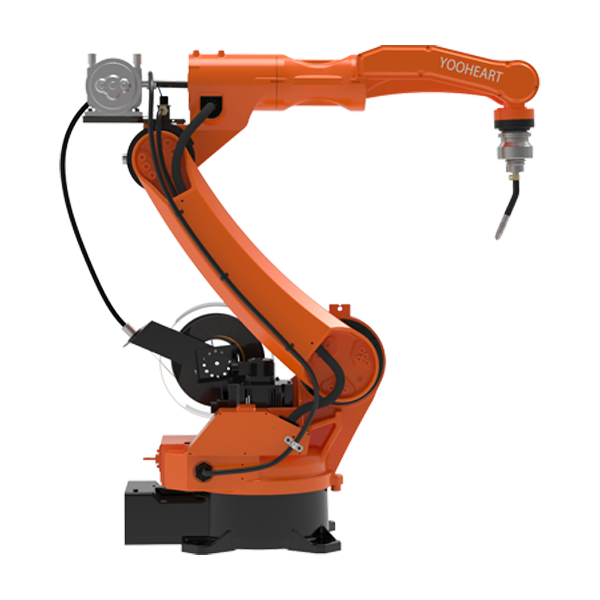

1. Robot body

HY1165B-315 is the largest palletizing robot in the series of Yooheart handling robots. It has 165kg payload and 3150mm arm length. With advantages of high speed and stability as well as all axis operating at low power output, it can be widely used in lots of manufacturing industry such as furniture, food and beverage and 3C, applicable to high-speed and high-precision palletizing, picking, packaging, handling and feeding and unloading.

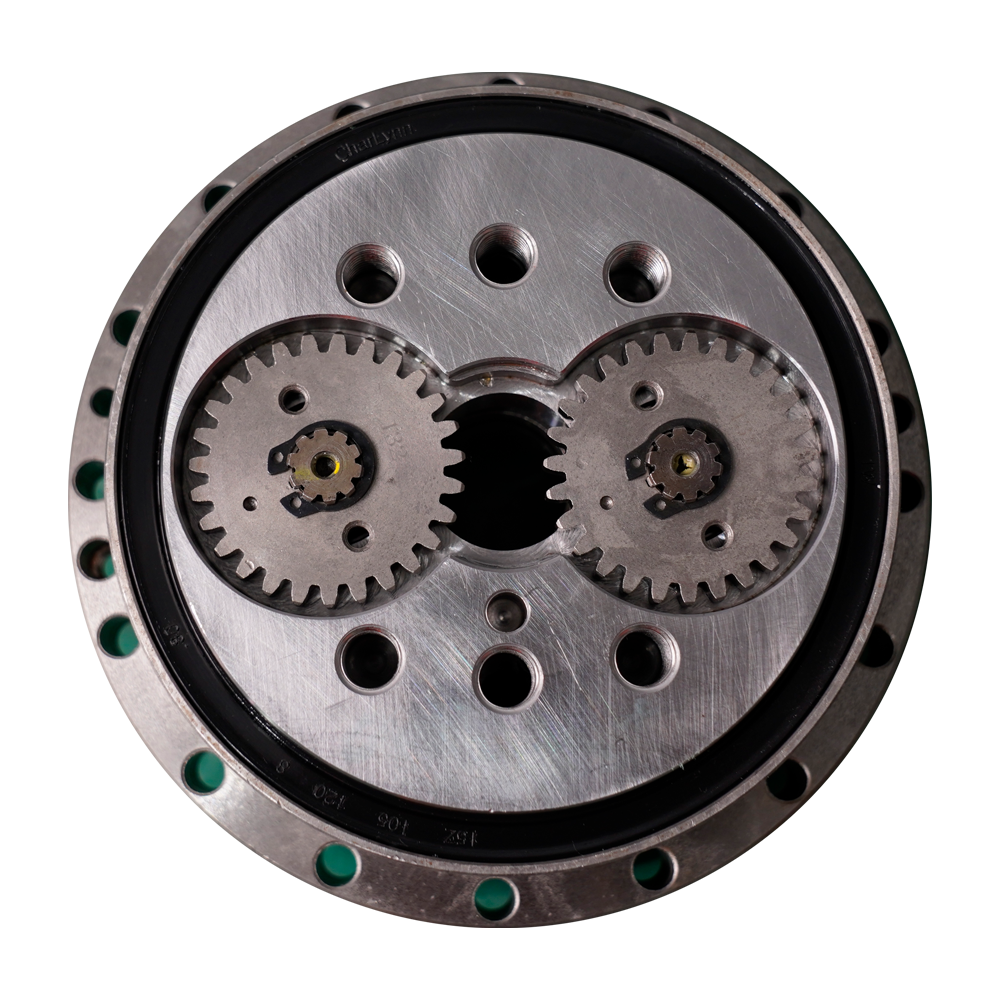

2. Reducer

Different sizes of reducers have been installed different joints of the palletizing robot. For heavy load palletizing robots, the stability and good performance of reducer are the important aspects. When the load is large, it is not cost-effective to increase the power of the servo motor blindly, and the output torque can be improved through the reducer in the appropriate speed range.

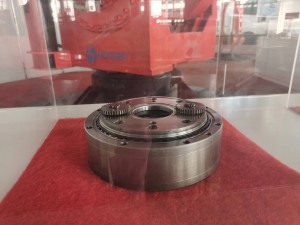

Yooheart robots are fitted with two types of reducer, one is RV reducer which is developed by ourselves. Yooheart have a complete technological R&D team to develop RV reducer. Yooheart RV reducer has the advantages of stable running, low noise and its speed ratio selection space is large so that it can ensure accurate and reliable operation of robots that work long hours and periodically

Another is harmonic reducer. It is usually installed in small arms of robots like the fifth joint and the sixth joint. The reducer we used is Nidec, a brand from Japan. This brand is the world's number one in the field of precision small reducer products.

3. Programming system

LNC system is the user-friendly software. Even users who have no robot operation experience can create programs easily and fast. Through the teaching pendant, you can easily operate the robot to serve you.

Robot debugging and testing

Before the delivery, we will check the robot carefully. The whole debug is divided into 16 large items and 64 small items such as confirming basic parameters, point correction, welding test, external shaft function test, ontology test, control cabinet inspection and other 64 items of inspection. Every time a technician tests something, they record it on this form. All assembled robots are thoroughly tested for 48 hours before leaving the factory to ensure there are no quality problems

Robot applications

1. HY1165B-315 palletizing robot is equipped with high precision gripper, which can achieve millimeter level repeated positioning accuracy, the minimum is ±8mm, and can accurately locate materials and specify transport positions. The fastest handling speed can reach 4s/ beat. Compared with manual delivery, the handling efficiency of the production line is increased by 30%, and the delivery error rate is reduced to 0, which can realize 7*24 hours of non-stop operation.

2. Palletizing robot for Non-woven fabric handling application

Non-woven fabric surface smooth, fragile, so manual handling, palletization is likely to cause damage to the product. At the same time, repeated handling and palletizing operations of production line employees throughout the day are easy to cause physical damage, and production efficiency will also be affected.Therefore, the choice of handling robot to replace manual handling and stacking of non-woven fabric can ensure the quality and integrity of the product.

Company profile

Anhui Yunhua Intelligent Equipment Co., Ltd. is a scientific and technological enterprise integrating R&D, production, sales and application with a registered capital of 60 million yuan. It has more than 200 employees and covers an area of more than 120 acres. Since its inception, Yunhua has obtained dozens of inventions and over 100 appearance patents products with strong strength, our products have passed IOS9001 and CE certifications, we can provide industrial robots with various functions and the corresponding complete set of solutions for the majority of users. After more than ten years of research and development technology precipitation, "Honyen" is innovating and creating a new brand "Yuooheart". Now we are moving on with new Yooheart robots. Our self-developed RV reducers breakthrough more than 430 manufacturing difficulties and have achieved the domestic RV reducer mass production. Yunhua is committed to building a domestic first-class robot brand. We believe through all efforts of Yunhua, we can achieve the "unmanned chemical plant"

After-service

We have a perfect after service to help you learn the operation even if you have never used industrial robots and solve problems during your use time.

First, we will provide the related manuals to help you understand some robot information.

Second, we will provide a series of teaching videos. You can follow these videos step by step from wiring, simple programming to completing complex programs. It is the most efficient way to help you under the covid circumstance.

Last but not least, we will provide online service with more than 20 technicians. If you have any questions, you can contact us at any time and we will help you promptly.