YH1165B-315 Heavy-Duty Handling Robot for Large Workpiece Palletizing and Material Handling

Introduction

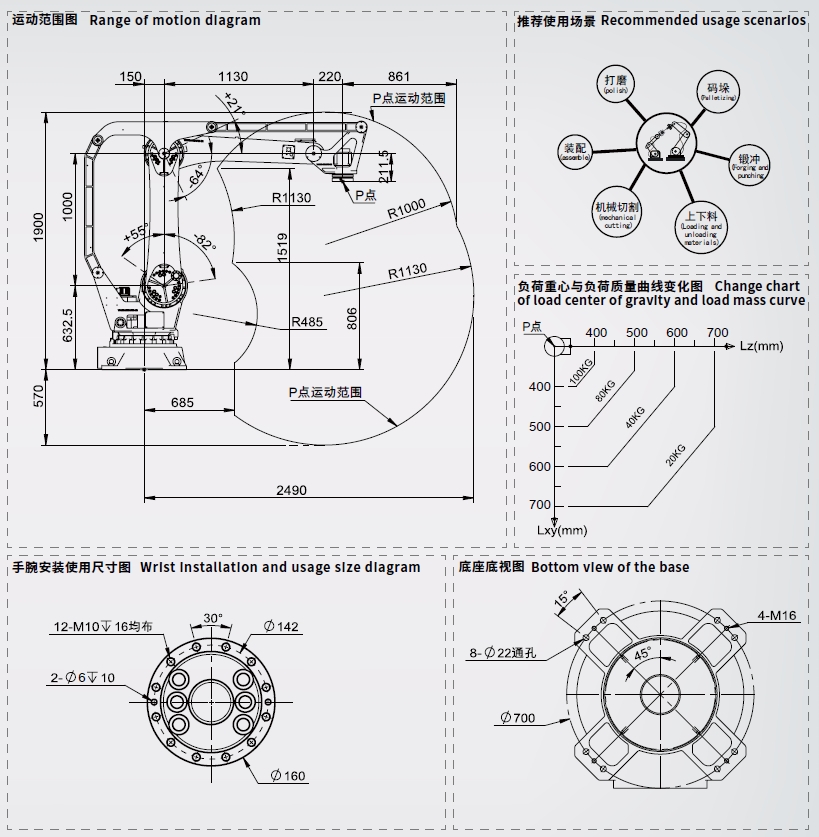

The YH1165B-315 is a high-performance 4-axis industrial robot designed for heavy-duty material handling and palletizing applications. Engineered to handle large and bulky workpieces such as bricks, oil drums, sacks, and crates, this robot combines robust load capacity, extended reach, and precision to optimize efficiency in demanding industrial environments. With a maximum payload of 165 kg and an arm span of 3150 mm, the YH1165B-315 excels in scenarios requiring rapid, stable, and repetitive operations. Its modular design ensures easy installation and maintenance, making it an ideal solution for industries seeking productivity and reliability.

Caption: YH1165B-315 efficiently palletizing oil drums in an industrial facility.

Key Features

- Heavy Load Capacity

Capable of handling payloads up to 165 kg, the YH1165B-315 is tailored for heavy industrial applications. Its reinforced joints and optimized mechanical structure ensure stability even under maximum load. - Extended Reach and Flexibility

With a 3150 mm arm length and 4-axis movement, the robot achieves a wide operational range, covering large workspaces while maintaining precision. The P-point (tool center point) motion range is designed to accommodate vertical and horizontal stacking tasks seamlessly. - High-Speed Stability

Advanced motion control algorithms and optimized joint mechanisms enable 15–20% faster cycle times compared to previous models. This upgrade ensures rapid task execution without compromising accuracy. - Easy Maintenance

The robot’s modular components and simplified wiring reduce downtime during maintenance. Critical parts are easily accessible, minimizing service interruptions. - Durable Construction

Built with industrial-grade materials, the YH1165B-315 withstands harsh environments, including dust, vibrations, and temperature fluctuations.

Caption: YH1165B-315 efficiently palletizing Bags.

Technical Specifications

| Parameter | Value |

| Payload Capacity | 165 kg (max) |

| Arm Length | 3150 mm |

| Axes | 4-axis |

| Repeatability | ±0.03 mm |

| Motion Range (P-Point) | Lz: 500–1100 mm (vertical) |

| Lxy: 500–1100 mm (horizontal) | |

| Speed Upgrade | 15–20% faster than predecessors |

| Recommended Applications | Palletizing, forging, machining, assembly |

Caption: P-point motion range diagram illustrating vertical (Lz) and horizontal (Lxy) coverage.

Applications

The YH1165B-315 is versatile across industries requiring heavy material handling. Key use cases include:

- Palletizing of Bulk Goods

Efficiently stack bricks, sacks, or crates in warehouses or production lines. The robot’s extended reach and payload capacity allow it to handle multiple layers with precision. - Forging and Punching

Withstand high-impact environments by transporting heavy metal components between forging presses or punching machines. - Machining and Assembly

Load/unload large parts onto CNC machines or assemble heavy components in automotive or machinery manufacturing. - Drum and Barrel Handling

Safely lift and position oil drums, chemical barrels, or similar cylindrical objects.

Caption: YH1165B-316 handling crates in a logistics warehouse.

Performance Enhancements

The upgraded YH1165B-315 model features:

- 15–20% faster cycle times due to enhanced servo motors and motion algorithms.

- Improved vibration damping for smoother operations.

- Energy-efficient components reducing power consumption by up to 10%.

Why Choose YH1165B-315?

- Reliability: Tested in real-world scenarios with over 10,000 hours of operation.

- Customization: Optional grippers, sensors, and software integration for specific tasks.

- Support: Comprehensive technical documentation and 24/7 customer service.

Request Additional Information

For detailed load center of gravity charts, base installation diagrams, or customized solutions, contact our technical team. Products marked with "*" require supplementary documentation.

Conclusion

The YH1165B-315 industrial robot redefines efficiency in heavy-duty material handling. Its combination of strength, speed, and adaptability makes it indispensable for industries aiming to streamline operations and reduce labor costs. Contact us today to explore how this robot can transform your workflow.