Robot Palletising Boxes - 4 Axis Stamping Robot For Press Machine – Yunhua

Robot Palletising Boxes - 4 Axis Stamping Robot For Press Machine – Yunhua Detail:

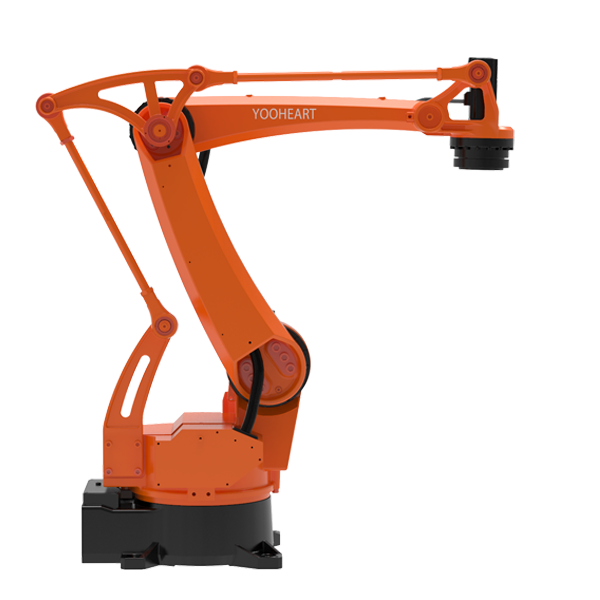

4 Axis Stamping Robot

Specially for Press Machine Automation

Product Introduction

Core Parts

All High Quality Chinese Brand Parts

Detail Show

High Precision

Fast action response

And the level is leading

in the country

Simple in structure

Easy to maintain

More cost-effective

High speed and stability

Precise path

Perfect Stamping solutions

Robot Parameter

|

Project |

Specification |

Project |

Specification |

Axis |

Motion range |

Max speed |

Hollow Dia |

|

Axis |

4 |

Temperature |

0℃-45℃ |

J1 |

±170º |

190º/s |

—— |

|

Capacity |

3.7KVA |

Humidity |

20-80%RH(No humidity) |

J2 |

+10º~+125º |

120º/s |

—— |

|

Weight |

170KG |

Vibration |

Under 4.9M/S ² |

J3 |

+10º~-95º |

120º/s |

—— |

|

Max payload |

10KG |

Others |

No flammable and corrosive gases and liquids, keep away from electrical noise sources |

J4 |

±360º |

200º/s |

—— |

|

Max work range |

140CM |

Repeatability |

±0.08mm |

IP level |

IP65 |

Installation |

Ground |

Robot Application

Hot extrusion product loading and unloading

This project is mainly for copper stamping forming. The red punching process is a hot extrusion process. During red punching, the metal material is heated to a certain temperature and put into the preheated mold. After the one-time reciprocating movement of the pressure machine tool, the metal material is plastic deformed to obtain the required size, shape and good mechanical properties of the stamping parts. The customer adopts Yooheart 4-axis handling robot to load and unload the red punching metal workpiece

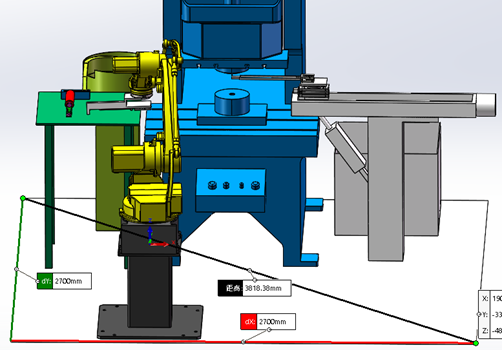

Integration Solution Overview

The project consists of a punching press, Yunhua 4-axis 10kg robot, secondary positioning tooling, cylinder combination blanking device and so on. The known data such as time beat, rated load and working condition are all in the rated parameter range of HY1010B-140.

Production process Overview

Manual feeding for hoist▶ vibration plate feeding ▶ Positioning of feeding device before heating ▶ eddy current tube heating ▶ secondary positioning fixture positioning▶ robot clamping▶ punch press pressing▶ cylinder feeding device discharging

After-Sale Service

We have a perfect after service to help you learn the operation even if you have never used industrial robots and solve problems during your use time.

First, we will provide the related manuals to help you understand some robot information.

Second, we will provide a series of teaching videos. You can follow these videos step by step from wiring, simple programming to completing complex programs. It is the most efficient way to help you under the covid circumstance.

Last but not least, we will provide online service with more than 20 technicians. If you have any questions, you can contact us at any time and we will help you promptly.

RFQ

Q. Is this safe for workers?

A. sure, one of the advantages of using robot for pick and place is protect workers from injuries. One worker can handle 5~6 units CNC machine.

Q. what kind of product can use loading and unloading robot?

A. Each robotic machine loader can be fitted with proper end-of-arm-tooling that is compatible with your machine and product. They are extremely accurate and also have the dexterity to handle the part with care.

Q. Only one end of arm tools can be used for loading and unloading robot?

A. Industrial robot arm can modify the program and the gripper clamp, rapid changes in the intelligent warehousing, debugging speed, eliminating the need for employees but also for the training time, can be quickly put into production.

Q. is there any other merit of loading and unloading robot?

A. Improve the quality of the workpiece Appearances: robot automated production lines, from feeding, clamping, cutting entirely by robots, to reduce intermediate links, part quality is greatly improved, especially more beautiful surface.

Q. Can you supply full solutions for loading and unloading robot?

A. sure, we can do that together with our dealer.

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Robot Palletising Boxes - 4 Axis Stamping Robot For Press Machine – Yunhua , The product will supply to all over the world, such as: Ukraine, Chile, Malta, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.