Robot For Palletizing - 4 Axis Stamping Robot For Press Machine – Yunhua

Robot For Palletizing - 4 Axis Stamping Robot For Press Machine – Yunhua Detail:

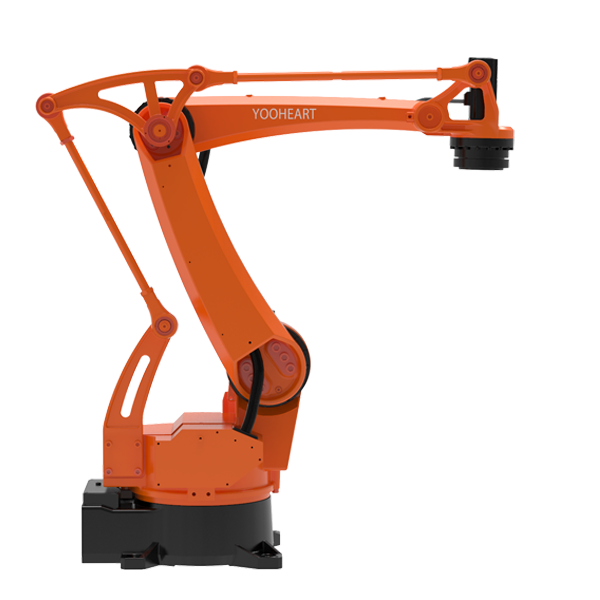

4 Axis Stamping Robot

Specially for Press Machine Automation

Product Introduction

In view of the actual demand for the upgrading and transformation of the stamping industry,a high flexibility and simple control 4-Axis stamping handling robot is designed and developed.

Four axis stamping robot adopts four axis design, compact shape, small size, light weight, widely used in argon arc welding, palletizing, handling, stamping and other fields, can complete stable handling, accurate welding. The four axis punching manipulator can carry out stamping operation flexibly in a small space, and it is simple and convenient to install and debug.

Core Parts

All High Quality Chinese Brand Parts

RV Reducer

Completely Made By Yunhua Company

Servo Motor

Top 3 Servo Motor Made in China

LNC CONTROL SYSTEM

TOP 1 IN AISA

Robot Body

Military Quality

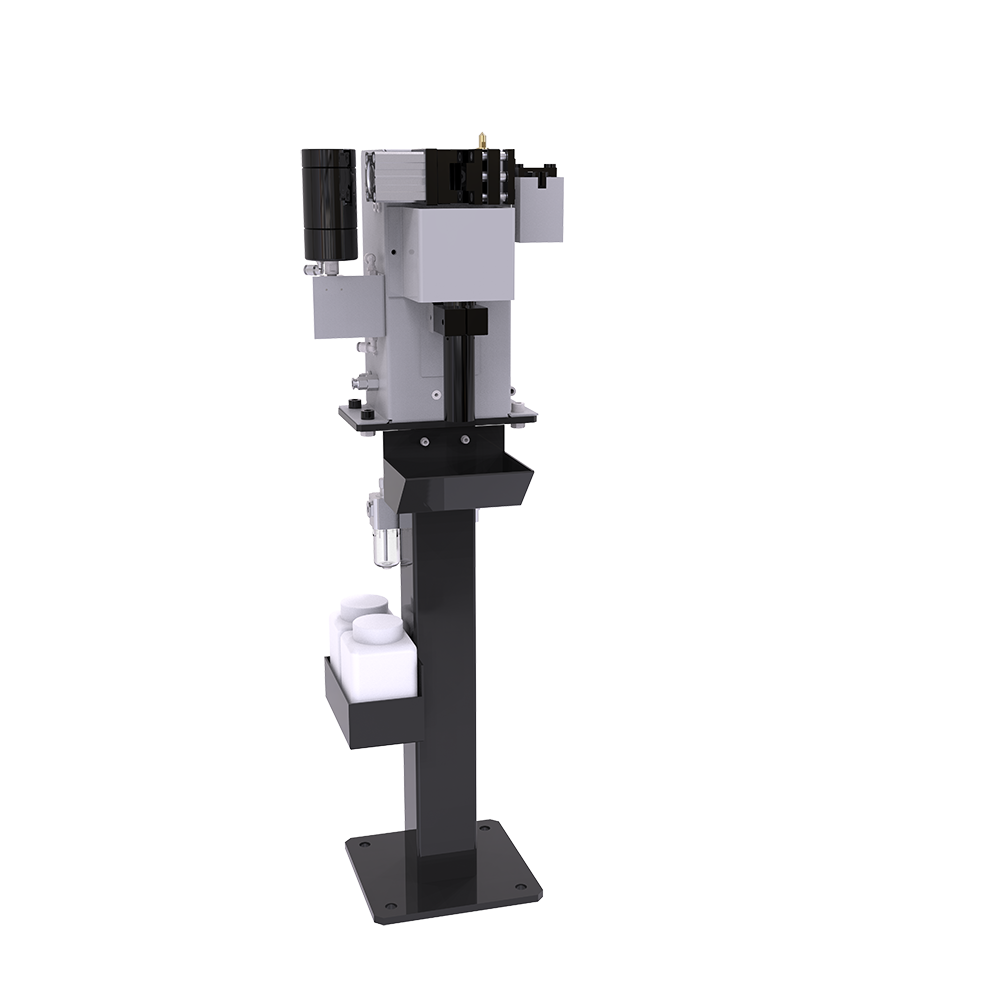

Detail Show

High Precision

Fast action response

And the level is leading

in the country

Adopt high configuration

Power combination,

Lightweight body design

Simple in structure

Easy to maintain

More cost-effective

High speed and stability

Precise path

Perfect Stamping solutions

Robot Parameter

|

Project |

Specification |

Project |

Specification |

Axis |

Motion range |

Max speed |

Hollow Dia |

|

Axis |

4 |

Temperature |

0℃-45℃ |

J1 |

±170º |

190º/s |

—— |

|

Capacity |

3.7KVA |

Humidity |

20-80%RH(No humidity) |

J2 |

+10º~+125º |

120º/s |

—— |

|

Weight |

170KG |

Vibration |

Under 4.9M/S ² |

J3 |

+10º~-95º |

120º/s |

—— |

|

Max payload |

10KG |

Others |

No flammable and corrosive gases and liquids, keep away from electrical noise sources |

J4 |

±360º |

200º/s |

—— |

|

Max work range |

140CM |

Repeatability |

±0.08mm |

IP level |

IP65 |

Installation |

Ground |

Robot Application

Sheet Metal Automatic

Stamping Line with Stamping Robot

Palletizing Application

Loading unloading App

RFQ

Q. Is this safe for workers?

A. sure, one of the advantages of using robot for pick and place is protect workers from injuries. One worker can handle 5~6 units CNC machine.

Q. what kind of product can use loading and unloading robot?

A. Each robotic machine loader can be fitted with proper end-of-arm-tooling that is compatible with your machine and product. They are extremely accurate and also have the dexterity to handle the part with care.

Q. Only one end of arm tools can be used for loading and unloading robot?

A. Industrial robot arm can modify the program and the gripper clamp, rapid changes in the intelligent warehousing, debugging speed, eliminating the need for employees but also for the training time, can be quickly put into production.

Q. is there any other merit of loading and unloading robot?

A. Improve the quality of the workpiece Appearances: robot automated production lines, from feeding, clamping, cutting entirely by robots, to reduce intermediate links, part quality is greatly improved, especially more beautiful surface.

Q. Can you supply full solutions for loading and unloading robot?

A. sure, we can do that together with our dealer.

Product detail pictures:

Related Product Guide:

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for Robot For Palletizing - 4 Axis Stamping Robot For Press Machine – Yunhua , The product will supply to all over the world, such as: The Swiss, Finland, Irish, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.