Pick And Place Robot Benefits - Loading and unloading robot for CNC lathe machine – Yunhua

Pick And Place Robot Benefits - Loading and unloading robot for CNC lathe machine – Yunhua Detail:

Introduction

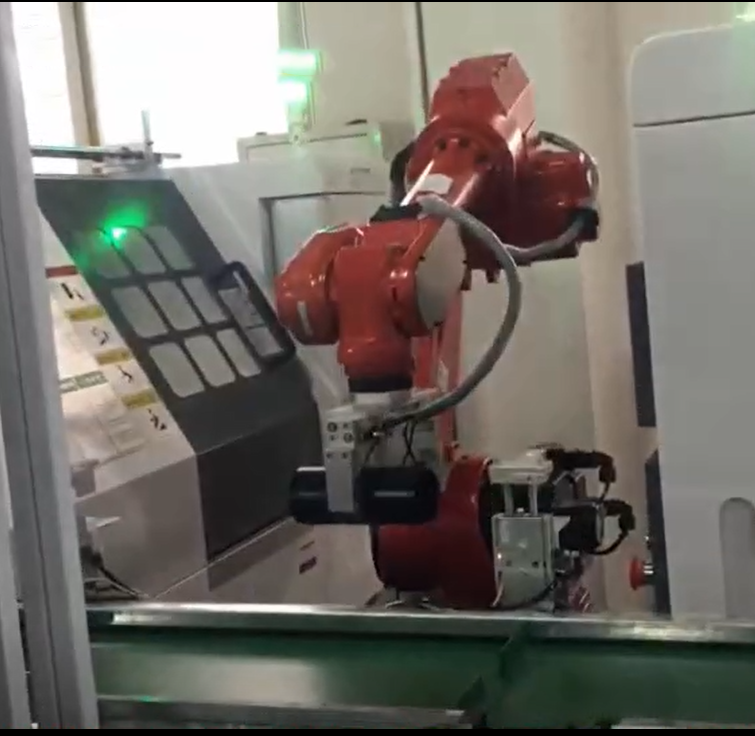

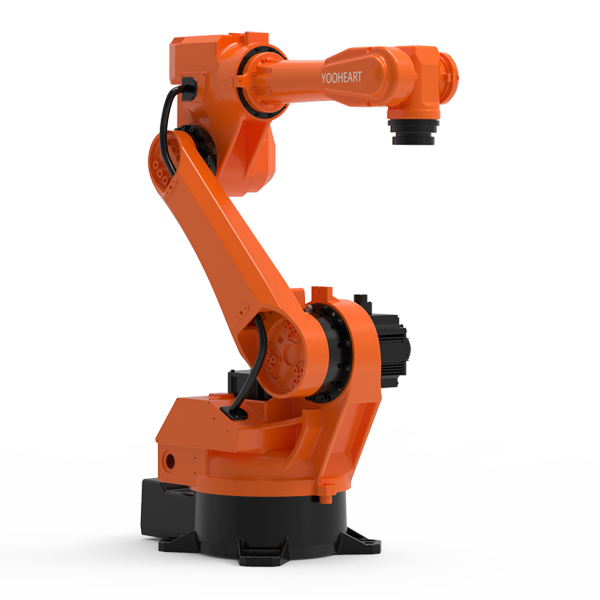

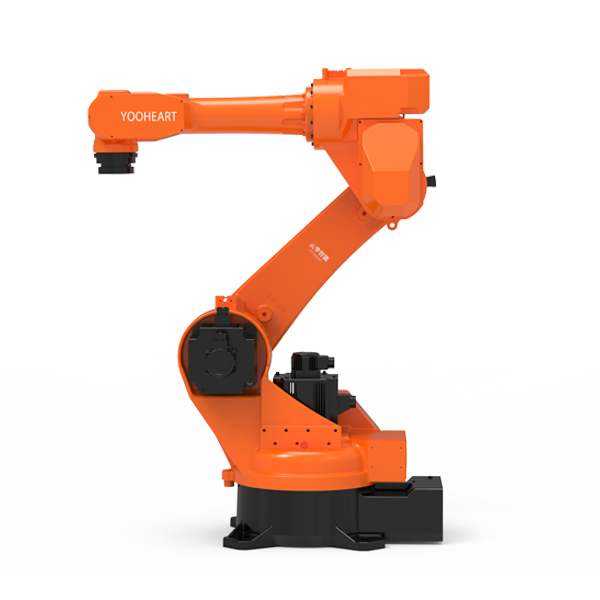

HY1020A-168 is a 6 axis robot mainly applied in loading and unloading. It is a mechanical arm controlled by numerical control system. With the help of human-computer interaction interface, which controls steering engine of each joint and its angle and send the command to the lower machine, HY1020A-168 robot will complete a series actions of automatic loading and unloading. It can replace manual loading and unloading operations and form efficient automatic loading and unloading system.

As a highly efficient automatic robot, HY1020A-168 has virtues of stable, reliable and continuous operation, high precision positioning, fast handling and clamping, shortening the working tempo. It can improve the single product manufacturing precision, speed up the mass production efficiency and quick and flexible to adapt to new tasks and new products, shorten delivery

CNC Machine Loading and 20kg robot for CNC Lathe Machine Loading and unloading App for CNC machine

Unloading Application

Technology data:

| Axis | MAWL | Positional repeatability | Powercapacity | Operating environment | Sheer weight | Installment | IP grade |

| 6 | 20KG | ±0.08mm | 8.0KVA | 0-45℃20-80%RH(no frost) | 330KG | Ground, hoisting | IP54/IP65(waist) |

| J1 | J2 | J3 | J4 | J5 | J6 | ||

| Scope of action | ±170° | +80°~-150° | +95°~-72° | ±170° | ±120° | ±360° | |

| Maxi speed | 150°/s | 140°/s | 140°/s | 173°/s | 172°/s | 332°/s |

Working Range

Delivery and shipment

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOO HEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOO HEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.what does this robot used for?

A.Robotic Loading and unloading are made for machine tools. The production line loading and unloading a workpiece flip, turn the work order and the like.

Q2.What about the loading and unloading robot efficiency?

A.Using loading and unloading robot can increase productivity, robotic increases machine production by up to 20% over traditional method.

Q3.Can loading and unloading robot coordinate with vision sensor?

A.Vision can be used to find parts on belt conveyor or on pallet. This is based on you know YOO HEART robot much good.

Q4.How many payload do you have for loading and unloading robot?

A.Loading and unloading robot, pick and place robot too, YOO HEART robot from 3Kg to 165kg can be used for this work. 10kg and 20kg are frequently used.

Q5.Why should I use loading and unloading robot for my CNC machines?

A.This industrial automation robotics can improve production efficiency. Robotized machine feeding will increase productivity and free skilled workers for more stimulating and fruitful work.

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Pick And Place Robot Benefits - Loading and unloading robot for CNC lathe machine – Yunhua , The product will supply to all over the world, such as: Botswana, Chile, Luxemburg, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.