Palletizing Robot For Sale - Stamping robot for automatic press production line – Yunhua

Palletizing Robot For Sale - Stamping robot for automatic press production line – Yunhua Detail:

Introduction

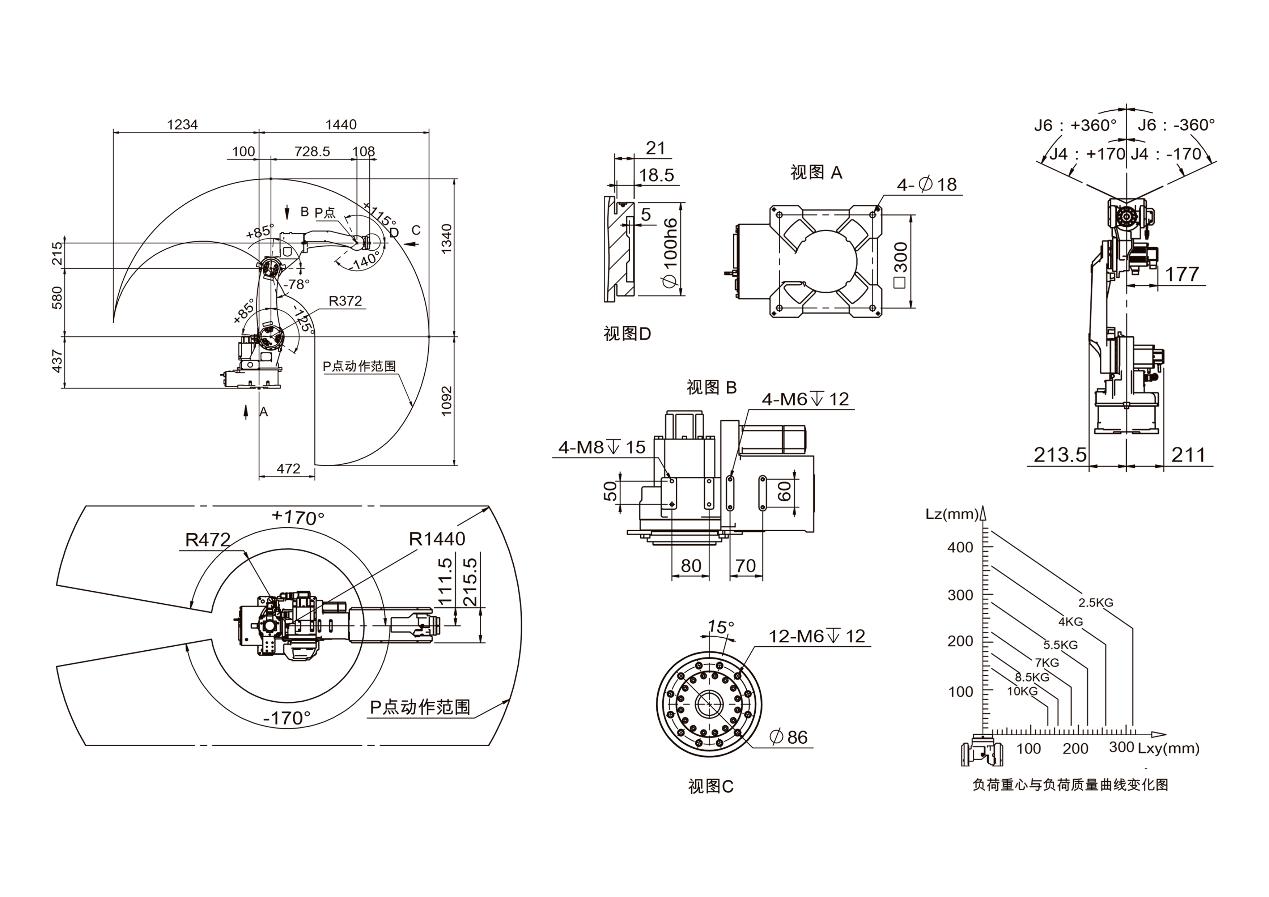

HY1010A-143 is a 6 axis handling robot which can be used for Handling, palletizing and depalletizing. Here it is used for stamping function for press machine. For some special situations, the parts will have to change more pose in order to meet press machine’s requirements, So solutions ask for more DOF (degree of freedom) of robot. 1430mm arm reach with 10kg load can meet quite a lot brands of press machine.

| Axis | Max Payload | Repeatibility | Capacity | Environment | Weight | Installation | IP level |

| 6 | 10KG | ±0.08 | 3kva | 0-45℃No humidity | 170kg | Ground/wall/ceiling | IP65 |

| Motion range J1 | J2 | J3 | J4 | J5 | J6 | ||

| ±170° | +85°~-125° | +85°~-78° | ±170° | ±115°~-140° | ±360° | ||

| Max Speed J1 | J2 | J3 | J4 | J5 | J6 | ||

| 180°/S | 133°/S | 140°/S | 217°/S | 172°/S | 172°/S | ||

Working Range

Delivery and shipment

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOOHEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOOHEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FAQ

Q. What’s the difference between 6 axis stamping robot and 4 axis stamping robot?

A. They both belong to stamping robot for press machine, if your press machine need more pose, 6 axis robot will be better. If not, you can choose 4 axis stamping robot.

Q. How many stamping robot will be used for a full automatic stamping production line?

A. that’s depend, usually one press machine need one stamping robot.

Q. How many employee will be needed for a stamping line?

A. 1-2 employee for 10 units of stamping robot.

Q. Can I send my man to your factory for training?

A. sure, you will have free training in our factory. And you are always welcome to here.

Q. Have you ever finished automatic stamping production line on over sea market?

A. At present, we didn’t.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Palletizing Robot For Sale - Stamping robot for automatic press production line – Yunhua , The product will supply to all over the world, such as: Ghana, Amsterdam, Ecuador, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!