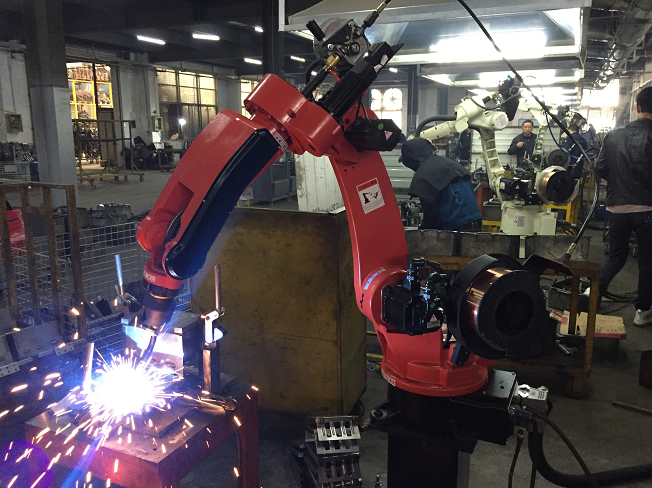

At this stage, welding robots have been widely used in automobile manufacturing, electric welding of chassis, seat skeleton diagrams, slide rails, mufflers and their torque converters, etc., especially in the production and manufacturing of chassis electric welding and welding. use.

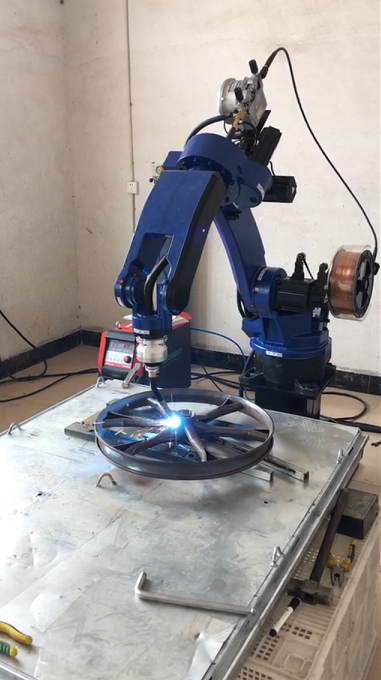

Automotive companies have decided to equip welding as the norm, using this kind of technology to improve the quality of electric welding, and even try to use it to replace some arc welding operations. The time inside the short line is also drastically reduced. Recently released a welding robot with a low aspect ratio, which is used to weld the lower parts of the body by electric welding. This kind of short welding intelligent robot can be assembled with taller robots to produce and process the upper end of the body, thereby reducing the length of the entire electric welding production line.

Most of the automobile chassis parts such as rear axle, sub-frame, crank arm, suspension system, shock absorber, etc. produced should be support safety parts dominated by MIG welding method. It is 1.5~4mm. The key of electric welding is dominated by lap joints and fillet joints. The quality of electric welding and welding is very high, and its quality is harmful to the safety factor of the car. After the welding robot is used, the appearance and essential quality of the weldment are further improved, and the reliability of the quality is ensured, the labor efficiency is reduced, and the labor environment is improved.

Post time: Mar-21-2022