Industrial robots, as the name implies, refer to robots used in industrial scenes. For fields requiring mass production, the 24-hour operation of industrial robots can help enterprises greatly improve production efficiency and reduce production costs.It can be seen that many factories have begun to use robots in production, so what are the advantages of robots compared with ordinary machines?First common machine often need through manual control to get the job done, but the robot will be more convenient, by setting the programming, the robot automatic repetition, multifarious work such as handling, welding, stowage, loading, etc., the second robot is safer, manual operation can’t always avoid employee injury or damage caused by improper operation machine,And automated unmanned chemical plants can perfectly solve this problem.

I. How does a industrial robot work?

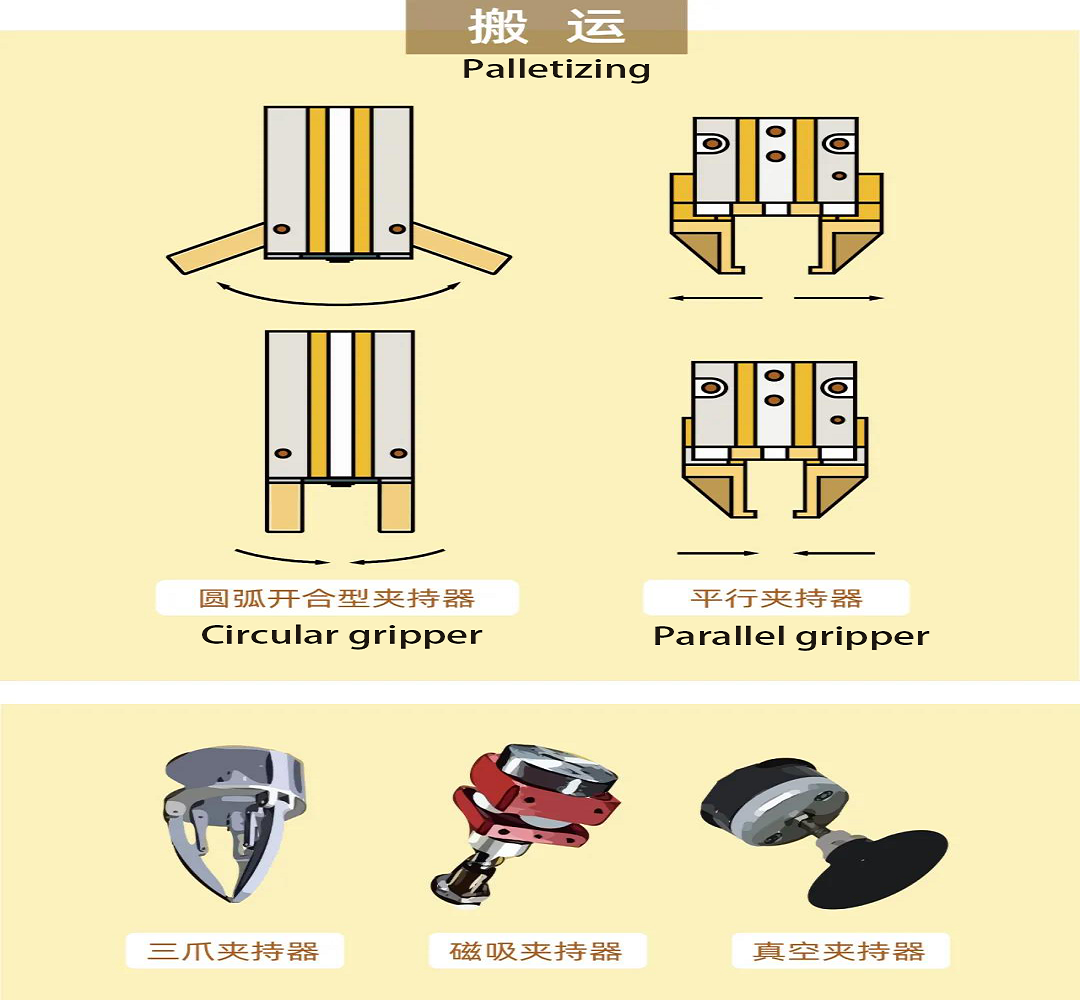

The gripper can be installed on the end of the industrial robot arm for handling.The most common type of gripper is the parallel gripper, which clamps objects by parallel movement.There is also a circular gripper, which opens and closes along the center point to pick up items.

In addition, there are three jaw gripper, vacuum gripper, magnetic gripper and so on.Different pickers can be matched according to different purposes.

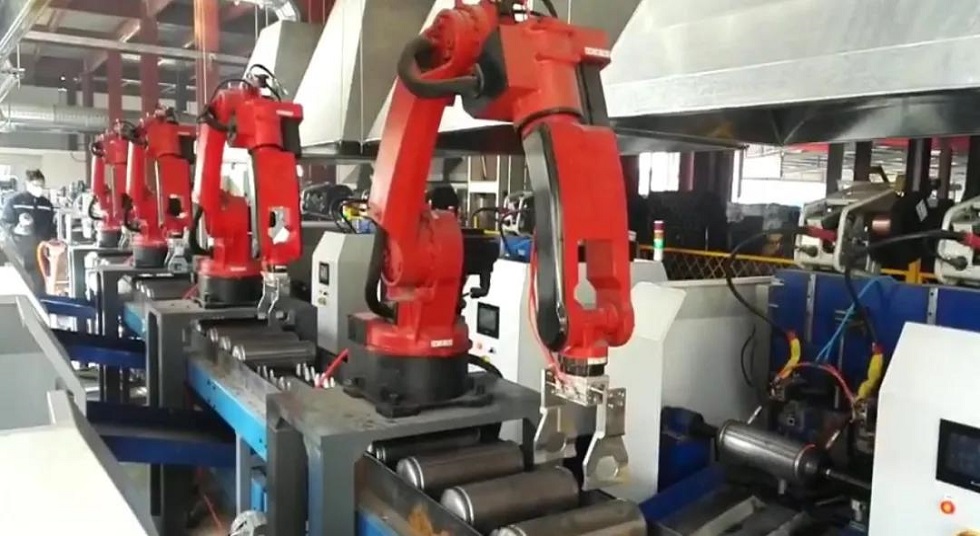

II. Common robotic workstations

-

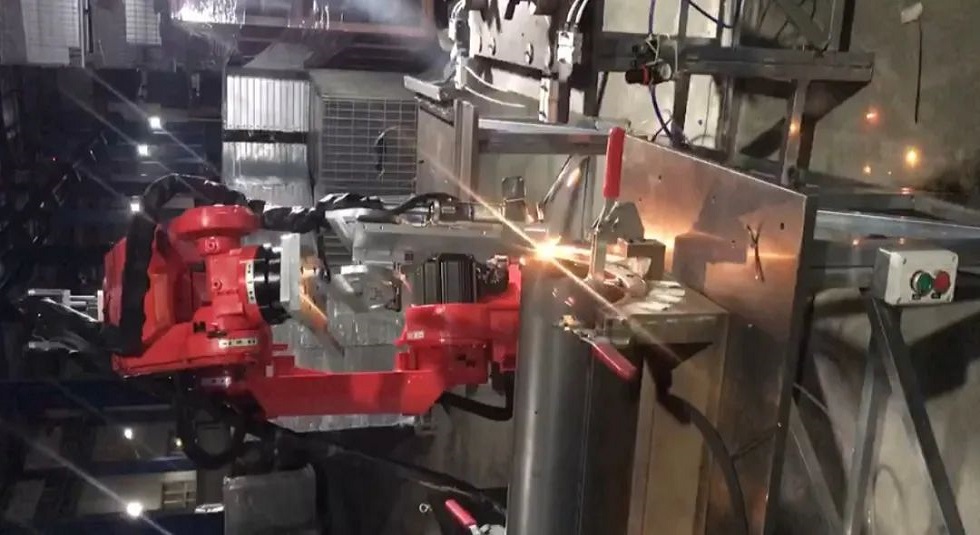

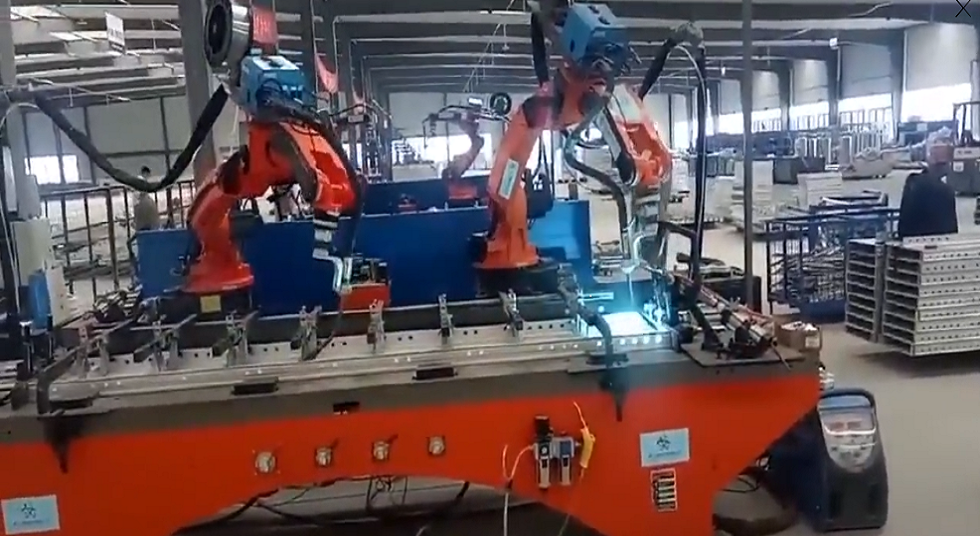

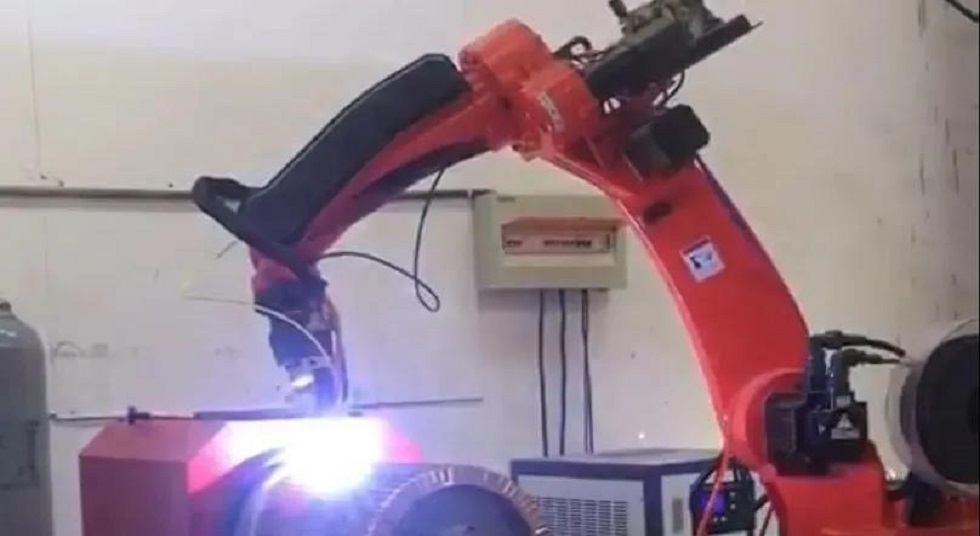

Welding workstations

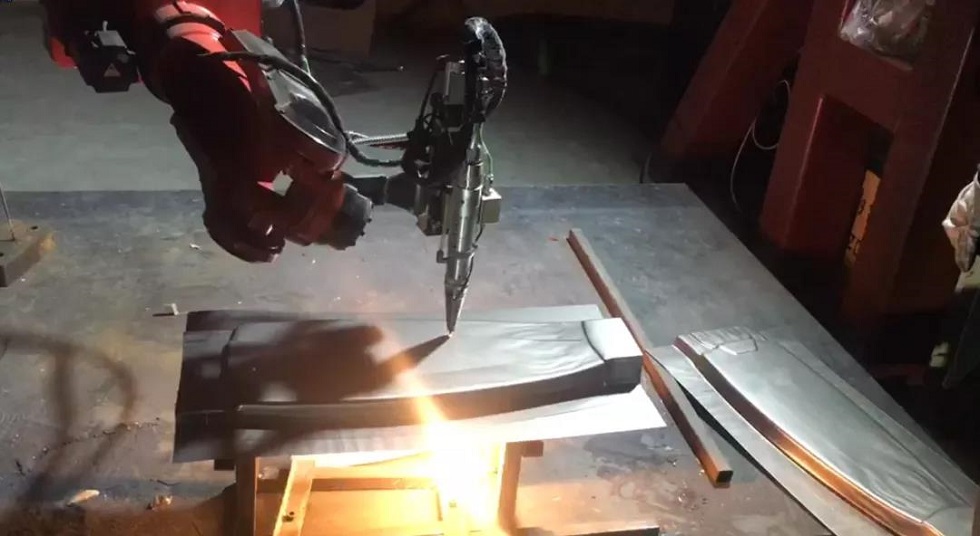

Laser Welding

Laser Welding

Aluminum Welding

Tig welding

- Cutting workstation

- Palletizing workstation

- Loading and Unloading Workstation

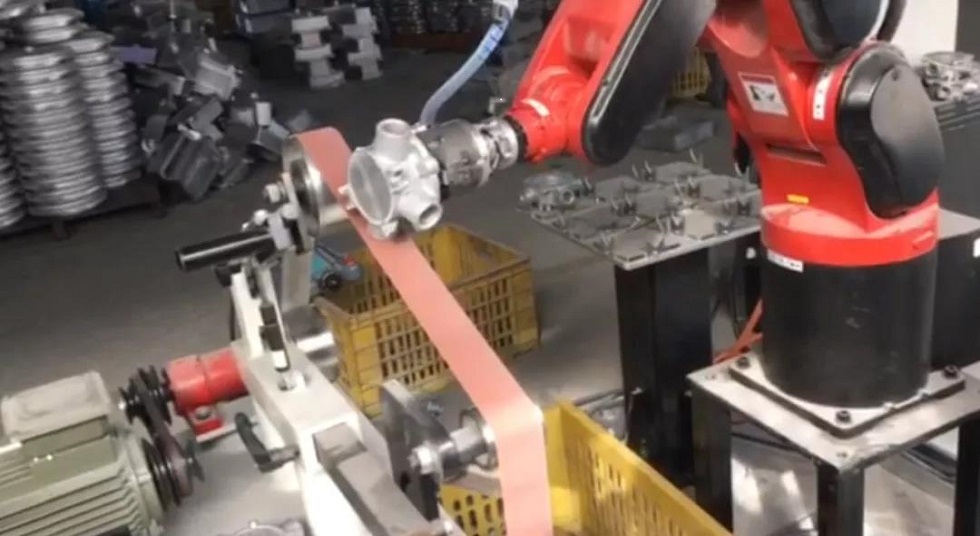

- Polishing Workstation

- Painting Workstation

Post time: Dec-13-2021