Introduction

The automotive manufacturing sector is increasingly reliant on industrial robots to achieve precision, efficiency, and consistency in production. Among the most critical applications is the welding of automotive components, particularly axles (also known as vehicle axles or car axles), which are essential for vehicle stability, power transmission, and load-bearing. This article explores how advanced robotic welding systems are revolutionizing the production of axles and other automotive parts, while highlighting the top keywords in both automotive components and welding robotics.

Section 1: Key Automotive Components in Focus

Automotive manufacturing involves intricate assemblies, with the following components being vital for vehicle functionality. Here are the top 5 automotive component keywords relevant to this discussion:

- Axle (Vehicle Axle/Car Axle)

Axles are central to a vehicle’s drivetrain, connecting wheels and supporting the vehicle’s weight. Precision welding ensures structural integrity and durability. - Suspension Systems

Components like control arms and struts require robust welding to withstand road stress. - Drivetrain Components

Parts such as differential housings and transmission mounts rely on high-strength welds. - Chassis Frames

The backbone of a vehicle, chassis frames demand consistent weld quality for safety. - Exhaust Systems

Complex welds on manifolds and pipes must resist heat and corrosion.

Of these, axle welding stands out due to its technical complexity and impact on vehicle performance.

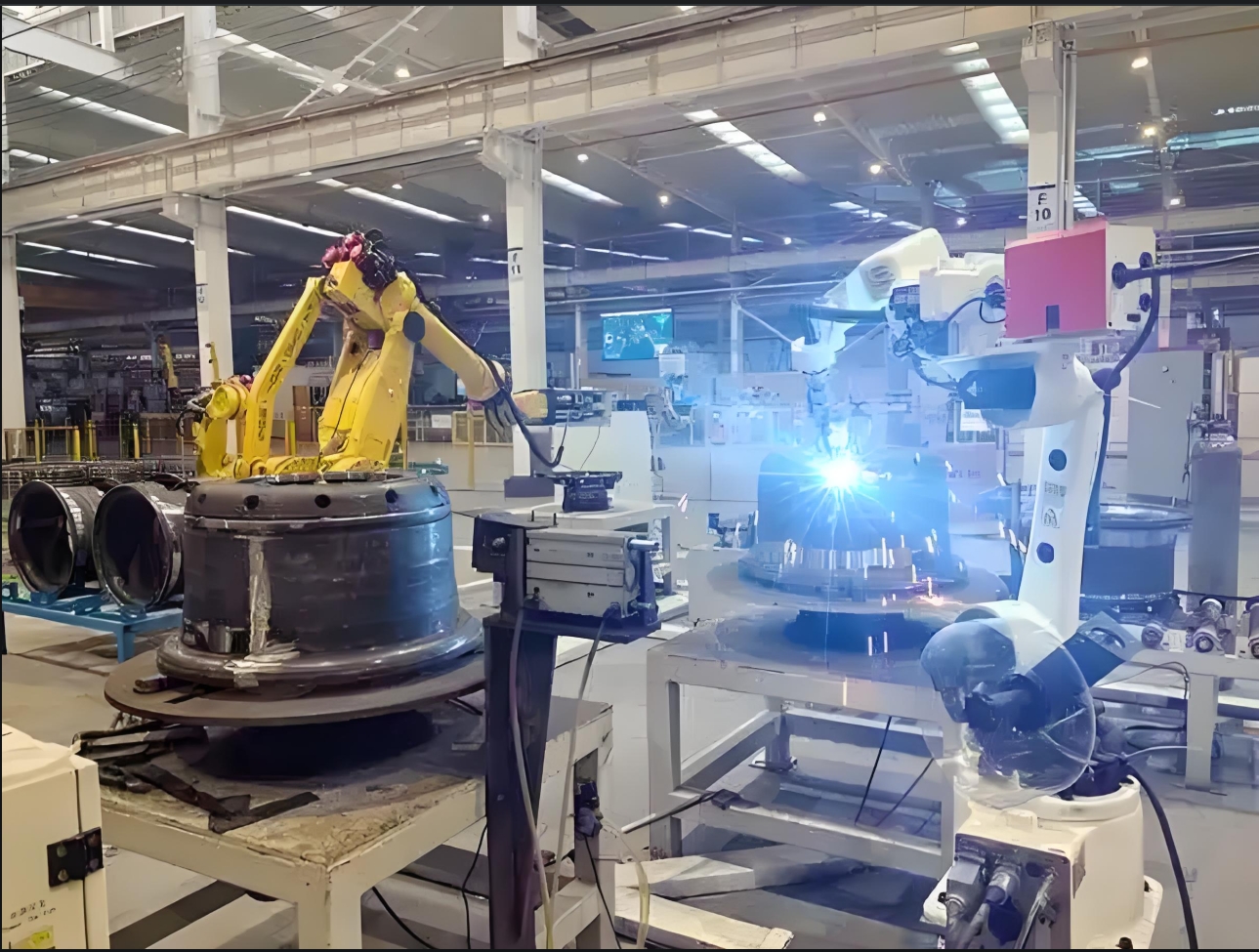

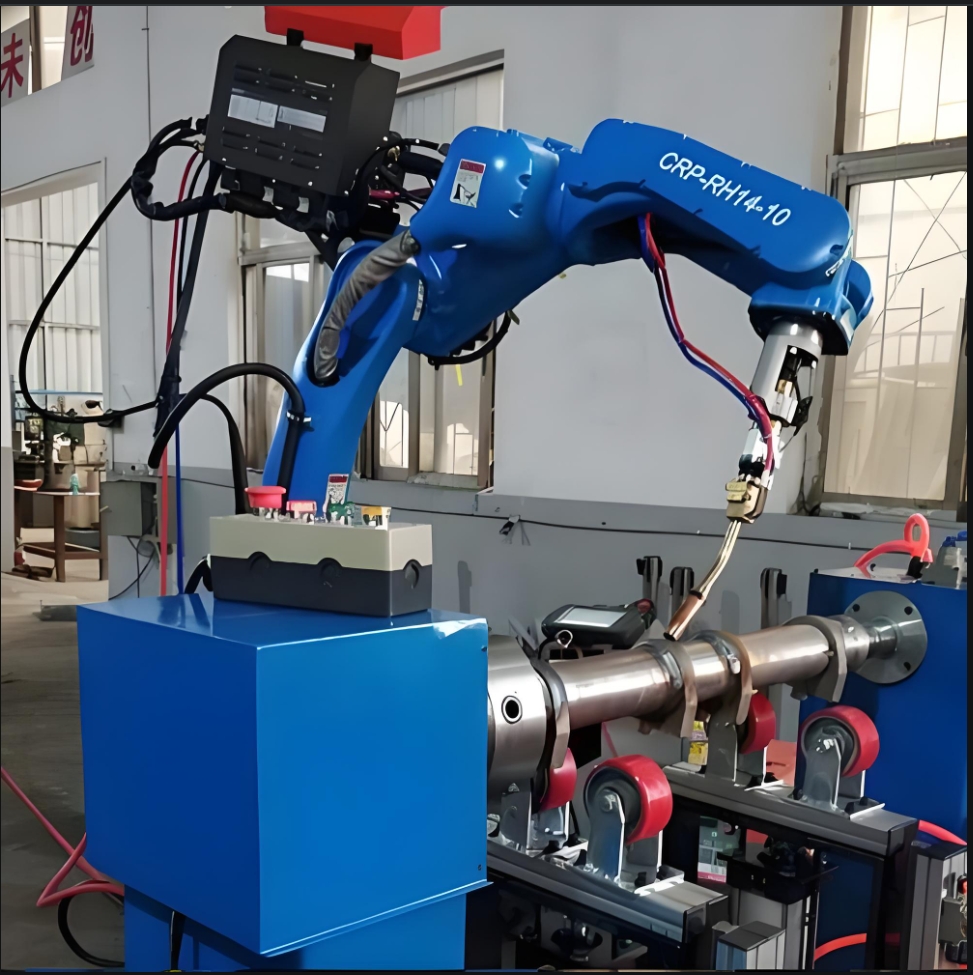

Section 2: Industrial Welding Robots: Technology and Capabilities

Modern robotic welding systems integrate advanced technologies to meet automotive standards. Below are the top 5 welding robot keywords:

- Automated Welding

Automation ensures repeatability and reduces human error in high-volume production. - Arc Welding (MIG/TIG)

Preferred for axle fabrication due to deep penetration and strong joint formation. - Laser Welding

Used for high-precision tasks, such as welding thin axle shafts with minimal distortion. - Spot Welding

Ideal for joining overlapping metal sheets in suspension or chassis components. - Collaborative Robots (Cobots)

Enhance flexibility in mixed-production environments, working alongside technicians.

These technologies enable manufacturers to achieve zero-defect welding on critical components like axles.

Section 3: Welding Axles with Industrial Robots: Process and Benefits

Step 1: Design and Programming

Axle welding begins with CAD/CAM simulations to optimize weld paths. Robots are programmed for multi-axis movements, ensuring access to complex geometries.

Step 2: Material Preparation

Axles are typically made from high-strength steel or aluminum alloys. Robotic systems pre-clean surfaces and clamp parts to minimize misalignment.

Step 3: Welding Execution

- Arc Welding: Used for thick axle housings, ensuring deep, uniform seams.

- Laser Welding: Applied to precision joints in lightweight axle designs.

- Seam Tracking Sensors: Compensate for material inconsistencies in real time.

Benefits of Robotic Axle Welding:

- Enhanced Strength: Consistent welds reduce weak points.

- Faster Cycle Times: Robots operate 24/7, boosting output.

- Cost Savings: Lower scrap rates and reduced labor costs.

- Safety: Eliminates exposure to sparks and fumes for workers.

Section 4: Industry Trends Shaping Robotic Welding

- AI-Powered Quality Control

Machine learning algorithms analyze weld integrity, flagging defects in real time. - Lightweighting Demands

Robots adapt to weld advanced materials like aluminum-carbon composites for electric vehicle (EV) axles. - IoT Integration

Smart robots transmit performance data to central systems for predictive maintenance. - Sustainability

Energy-efficient welding processes reduce carbon footprints.

These trends position robotic welding systems as indispensable in modern automotive factories.

Section 5: Challenges and Solutions

While robotic welding offers immense advantages, challenges persist:

- High Initial Investment: Mitigated by long-term ROI from increased productivity.

- Complex Programming: Simplified via user-friendly interfaces and offline simulation tools.

- Material Variability: Addressed with adaptive sensors and AI-driven adjustments.

For axle welding, partnering with experienced industrial robot manufacturers ensures tailored solutions.

Conclusion

The welding of automotive components like axles exemplifies the transformative power of industrial robots. By leveraging automated welding, arc welding, and laser welding technologies, manufacturers achieve unparalleled precision and efficiency. As the automotive industry evolves—particularly with the rise of EVs—robotic welding systems will remain central to producing durable, high-performance components. For businesses seeking to modernize their production lines, investing in advanced welding robotics is not just an option but a necessity.

Keywords: Axle, Vehicle Axle, Suspension Systems, Drivetrain Components, Chassis Frames; Automated Welding, Robotic Welding Systems, Arc Welding, Laser Welding, Spot Welding.

Post time: Apr-02-2025