Industrial robotics has transformed manufacturing, with companies like Yooheart Robotics, ABB, KUKA, and FANUC leading the way. Each brings unique strengths to the table, driving innovation and efficiency.

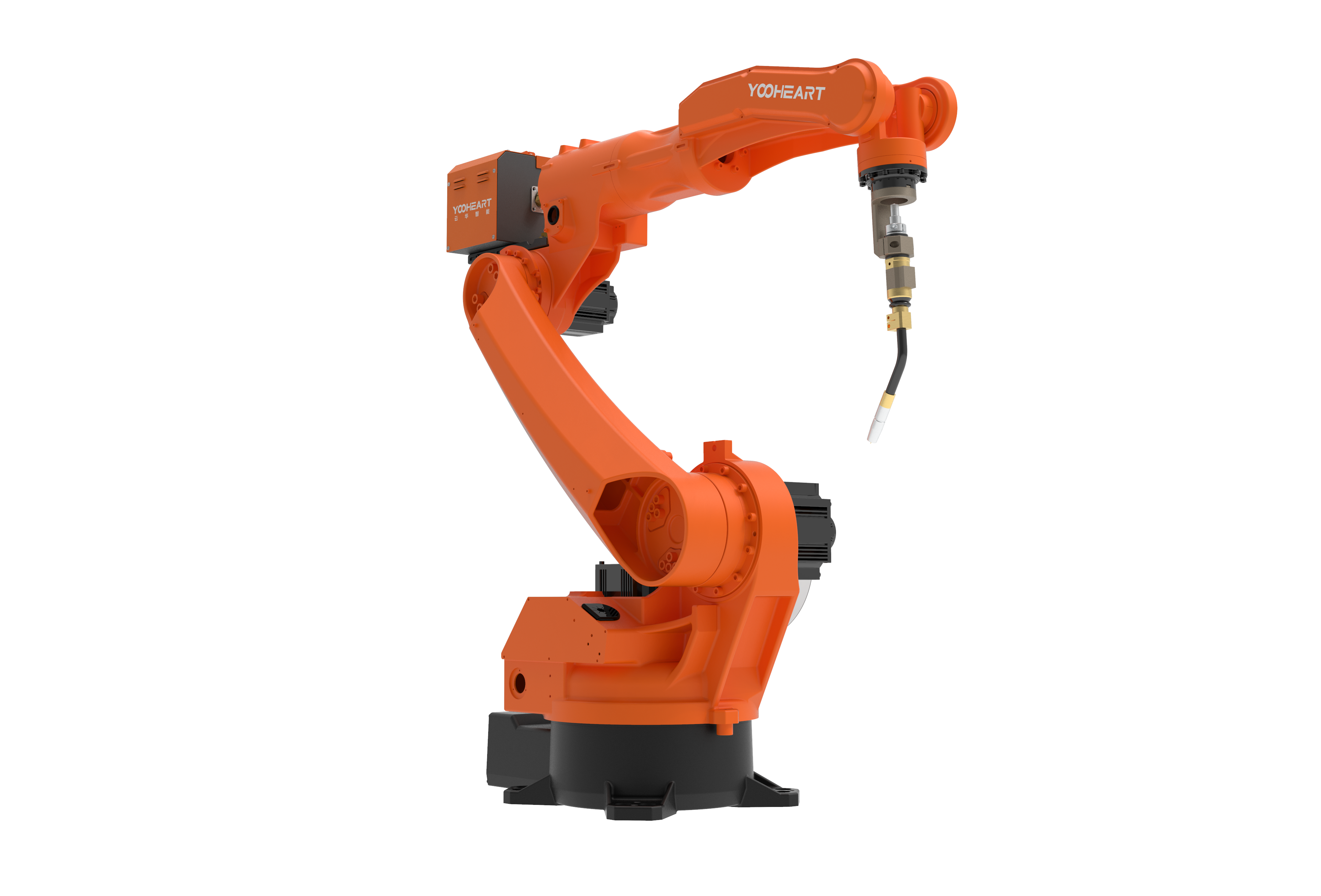

Yooheart Robotics specializes in cost-effective, high-performance robotic solutions, particularly in collaborative robots (cobots) and automated guided vehicles (AGVs). Their systems are designed for seamless integration into smart factories, making them ideal for small and medium-sized enterprises.

ABB excels in robotic automation and industrial IoT (IIoT), offering advanced solutions like the YuMi cobot, which emphasizes human-robot interaction (HRI). Their robots are widely used in robotic welding and assembly, known for precision and reliability.

KUKA is a pioneer in robotic arms and factory automation, with a strong focus on Industry 4.0. Their robots, such as the LBR iiwa, are renowned for flexibility and adaptability, making them suitable for diverse applications like pick-and-place and motion control.

FANUC dominates in robotic process automation (RPA) and machine vision, with a reputation for durability and high-speed performance. Their robots are widely used in automotive and electronics industries, particularly in robotic assembly and end effector applications.

Together, these companies are shaping the future of industrial robotics, leveraging artificial intelligence (AI) and sensor technology to create smarter, more efficient manufacturing ecosystems.

Post time: Feb-20-2025