In recent years, with the continuous development of industrial automation, more and more manufacturers have stepped into semi-automated or automated production systems. More and more traditional factories are also paying attention to automated production systems and equipment in order to improve production competitiveness, achieve higher production efficiency, and reduce manufacturing costs.

Advanced automation equipment can complete operations according to relevant instructions, reduce errors and improve efficiency, and is widely used in all walks of life. But in a complex automation environment, people and machines work together on some potentially dangerous mechanical equipment, such as stamping machinery, shearing equipment, metal cutting equipment, automated assembly lines, automated welding lines, mechanical conveying and handling equipment, hazardous areas (Toxic, high pressure, high temperature, etc.), it is easy to cause personal injury to the worker. Safety light curtains is an advanced technology to protect workers around various dangerous machinery and equipment.

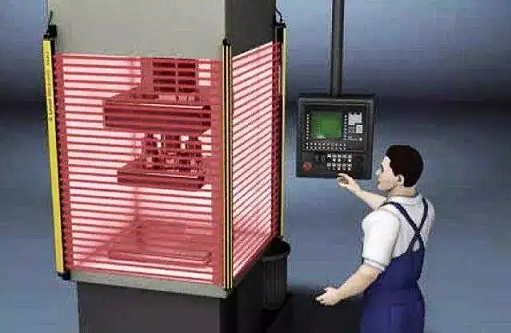

Safety grating is also called safety light curtain, also known as photoelectric protector, infrared protection device, punch protector, etc. The principle of safety light curtains is to emit infrared beam through the transmitter and receive it by the receiver to form a protection area. When the beam is blocked, The safety light grid sends a signal in the shortest time to control the dangerous mechanical equipment to stop running, helping to effectively reduce the occurrence of safety accidents. Compared with traditional safety measures, such as mechanical fences, sliding doors, pullback restrictions, etc., safety light curtain are freer, more flexible, and reduce operator fatigue. By reasonably reducing the need for physical protection, safety light grids simplify those routine tasks such as installation, maintenance and repair of equipment.

Post time: Jun-07-2022