Industrial manufacturing is an important link to promoting economic and social development. At present, the research on automatic welding equipment is deepening and concrete, which makes it widely used in the production of various types of welding structures.

In the process of automatic welding, intelligent and digital reasonable control of welding assembly gap error to a certain extent, on this basis, also to the workpiece position difference, workpiece joint deviation and other factors to consider. Therefore, laser welding seam tracking technology plays an important role in the welding process.

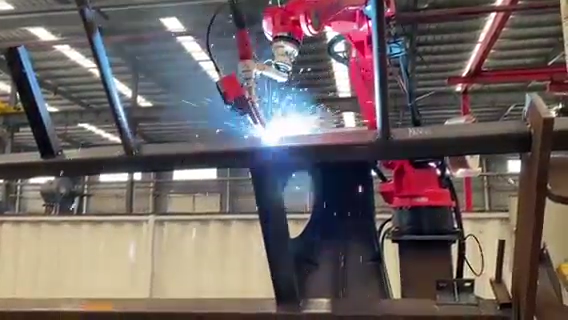

Cement tank car car base welding Seven axis earth orbit eight axis rotation with laser welding

-The position of the workpiece varies greatly

-Deviation exists at the workpiece connection

-High welding accuracy is required

-Poor welding environment and smoke

In this case, Yooheart intelligent robot HY1006A-145 is used for welding with laser welding seam tracking system, which has high flexibility, stability and reliability.

Before each welding, the equipment first scans and records the coordinate of the welding seam through the welding seam locating, and then calculates the coordinate offset by the internal algorithm and puts the reference coordinate parameters into the actual time to correct the actual deviation in time, so as to ensure the sealing and integrity of the product after welding.

"Four point intersection" method

As is known to all, two points determine a straight line, but the workpiece assembly will form the Angle, the conventional algorithm unable to determine its position, this requires using the method of "intersection" at four o 'clock, two lines intersecting produces the intersection point, the algorithm of special through the determination of known four points coordinates calculated the position of the intersection point coordinate, so as to achieve welding purpose.

Laser seam tracking system

The laser welding seam tracking system is mainly composed of laser sensors and monitoring terminals. The laser sensor is used for active acquisition and real-time processing of welding seam information, and maintains real-time communication with industrial robots. Monitoring terminal Monitors and configures sensors. The system also has the functions of locating, tracking and scanning before welding to meet the needs of intelligent welding.

Working principle: Weld seam scanning, point cloud image fitting, the algorithm accurately identify the feature points, and the real-time data of calculation results sent to the robot, into control instructions, modify or guide the robot operation.

Corrugated plate solution

Round hole automatic plug welding solution

Circular seam solution

Tubeplate solutions

Yunhua Intelligent can provide rapid deployment, safe and efficient automation solutions and real-time system solutions.The laser vision welding seam tracking system enables the welding robot to realize real-time welding seam locating and tracking, and correct the welding trajectory according to the welding seam offset in the welding process, so as to realize the real intelligent welding.

Post time: Apr-09-2022