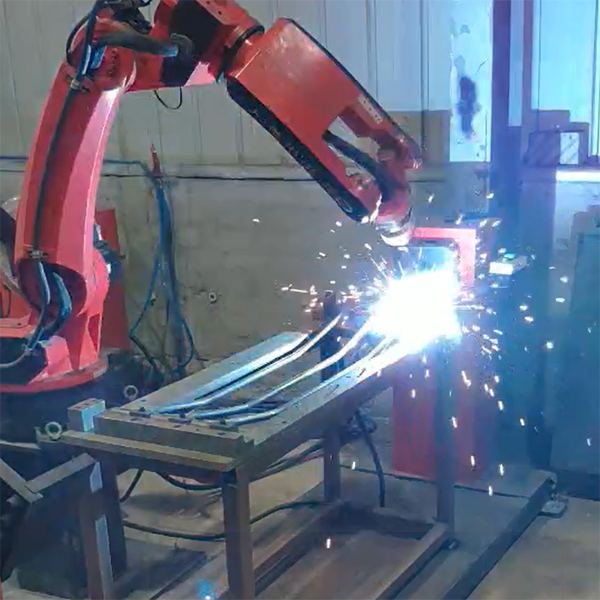

Automated welding solutions are used in a range of industries, most commonly in the automotive industry. Since the 1960s, arc welding has become automated and is a reliable manufacturing method that improves accuracy, safety, and efficiency.

The main driving force of automated welding solutions has always been the desire to reduce long-term costs and increase reliability and productivity.

However, there is now a new driving force, because robots are being used as a way to solve the skill gap in the welding industry. More experienced welders are retiring in large numbers, and there are not enough trained and certified welders to replace them.

The American Welding Society (AWS) estimates that by 2024, the industry will be short of nearly 400,000 welding operators. Robot welding is one of the solutions to this shortage problem.

Robot welding machines (such as Cobot welding machines) can be certified by welding inspectors. This means that the machine will be tested and inspected exactly the same as anyone wishing to be certified.

Companies that can provide robot welders will have a large upfront cost to purchase robots, but they will not have continuous salary payments afterwards. Other industries can rent robots for an hourly fee, and can reduce the additional costs or risks associated with them.

The ability to automate the welding process allows humans and robots to work side by side to better meet corporate requirements.

Kings of Welding’s John Ward explained: “We are seeing more and more welding companies have to abandon their operations due to labor shortages.

“Welding automation is not about replacing employees with robots. It is a key step in meeting the needs of the industry. Large jobs that require multiple welders in manufacturing or construction sometimes have to wait weeks or months to find a large number of certified welders.”

In fact, with robots, companies have the ability to allocate resources more efficiently to achieve the best results.

More experienced welders can handle more challenging and valuable welds, while robots can handle basic welds that can be achieved without much programming.

Professional welders usually have more flexibility than machines to adapt to different environments, and robots will obtain reliable results in setting parameters.

The robotic welding industry is expected to grow from 8.7% in 2019 to 2026. The automobile and transportation industries are expected to grow the fastest, and the demand for automobile manufacturing in emerging economies will increase. Electric vehicles are the two driving forces.

Welding robots are expected to become a key element to ensure the speed and reliability of product manufacturing.

The Asia-Pacific region has the highest growth rate. China and India are two key countries, both benefiting from government plans “Made in India” and “Made in China 2025″, which require welding as a key element of manufacturing.

For robotic automatic welding companies, all this is good news, and it provides excellent opportunities for companies in this field.

Submitted as follows: Manufacturing, promotion marked as: Automation, Industrial, Manufacturing, Robot, Robot, Welder, Welding

Robotics and Automation News was established in May 2015 and is now one of the most widely read websites in this category.

Please consider supporting us by becoming a paid subscriber, advertising and sponsorship, or purchasing products and services through our store-or a combination of all of the above.

This website and its related magazines and weekly newsletters are produced by a small team of experienced journalists and media professionals.

If you have any suggestions or comments, please feel free to contact us via any email address on our contact page.

The cookie settings on this website are set to “Allow Cookies” in order to provide you with the best browsing experience. If you continue to use this website without changing your cookie settings, or if you click “Accept” below, you agree to this.

Post time: Jun-06-2021