With the development of welding robot technology, more and more industries began to enjoy the dividend of intelligent welding, because it provides cost-effective technology for enterprises to achieve intelligence, information, and automation of welding products. In the heavy industry, the arc welding robot welding workstation, which integrates robot technology, welding process, mechanical design, sensing technology, automatic control technology, and MES system and other disciplines, mainly solves the automation equipment demand of welding process in manufacturing for the industry. Of course, no matter which industry to achieve intelligent welding, it is generally inseparable from high-quality welding wire, because the quality of the wire, will have a great impact on the stability of wire feeding in the welding process, welding quality, etc.

1 arc welding robot composition

An industrial robot is programmable, anthropomorphic, universal, and intelligent, and has been widely used in many industries. Industrial robots can be combined with other equipment to form different robot application directions, typical applications include welding, painting, assembly, collection and placement (such as packaging, palletizing, and SMT), product inspection and testing, etc.

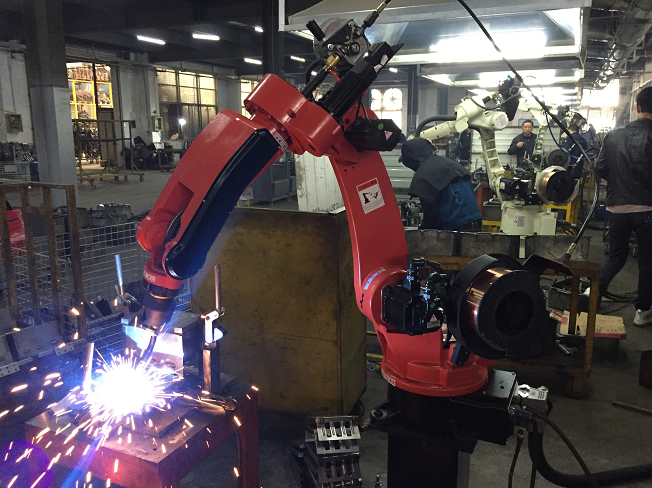

Arc welding robot is mainly composed of arc welding equipment and a robot system. The robot system is composed of a robot body and control cabinet (hardware and arc welding software, etc.).The arc welding equipment is composed of a welding power supply, wire feeding mechanism, welding gun and other parts. More intelligent robots are also equipped with laser or vision sensors and electrical control systems. A typical arc welding robot workstation is shown in Figure 1.

A typical application of 2 arc welding robot workstation

(1) Simple robot welding workstation The simplest way of arc welding robot workstation is a single robot, a single welding power supply, welding gun and simple fixture. This kind of robot welding workstation is the most basic, but also other complex robot welding production line components. Figure 2 shows a simple arc welding robot workstation. The robot of this workstation is the Fanuc robot, which is the actuator of the whole workstation system. The control cabinet is the brain center of the robot system, which is responsible for the data and signal transmission of the actuator and controls the movement of the actuator. The teaching device is a human-computer interface, on which the debugger can edit the program according to the requirements of the product. The welding power supply adopts a Lincoln welder, and the robot can communicate with the Arclink network, which is convenient for welding signal transmission between the robot and the welder.TBI welding gun and welding machine, welding wire and tooling constitute a complete path to achieve workpiece welding.

Through the construction of robot welding workstations, some simple industrial products can be realized automatic welding.As long as the position of the product in the tooling is well-positioned for a certain product, the online welding seam trajectory teaching program is carried out, and the process parameters of the solidified product are input, the robot can be started to realize the automatic welding of the product. The heavy plate welding with this welding workstation is beautiful in shape and good in quality.

This kind of robot welding workstation is especially suitable for some small workpiece welding, such as straight plate, round plate and other workpiece, strong adaptability, more compatibility; However, there is a problem with this kind of workstations: every time the products need to be loaded and unloaded manually, and the products cannot be automatically clamped, leading to the failure of the whole robot welding workstation to achieve fully automatic welding in the true sense.

welding robot welding workstation in addition to simple welding workstation basic equipment, also equipped with external electric control device, PC touch screen, jig, laser positioning system and dust collection device and monitoring system and so on, through these components to build a more complete welding arc welding robot workstation,Call it an intelligent robotic workstation.An intelligent robot welding workstation, its main definition is to be able to independently complete the welding work of a certain type of workpiece, and without any personnel to participate in the adjustment of equipment, that is, to realize the real unmanned operation.

Post time: Mar-25-2022