Recently, a Chinese robot has broken through a new technology, realizing an intelligent solution for laser engraving on rubber tires.

The scheme is mainly composed of a six-axis robot, 3D laser vision system, laser engraving system and McNum wheel universal alignment mechanism.

The program uses a new process, instead of the traditional production of embedded cycle card, steel receipt and vulcanized hollow bar code production process, the production of the workstation is fast, engraving clear and beautiful, smooth and smooth, no glue edge, etc., on the basis of meeting the production process, greatly improve the product phase grade.

At the same time, compared with the previous mold process, the solution can flexibly achieve DIY personalized customization, such as carving anti-channeling QR code, customized small batch, personalized LOGO.

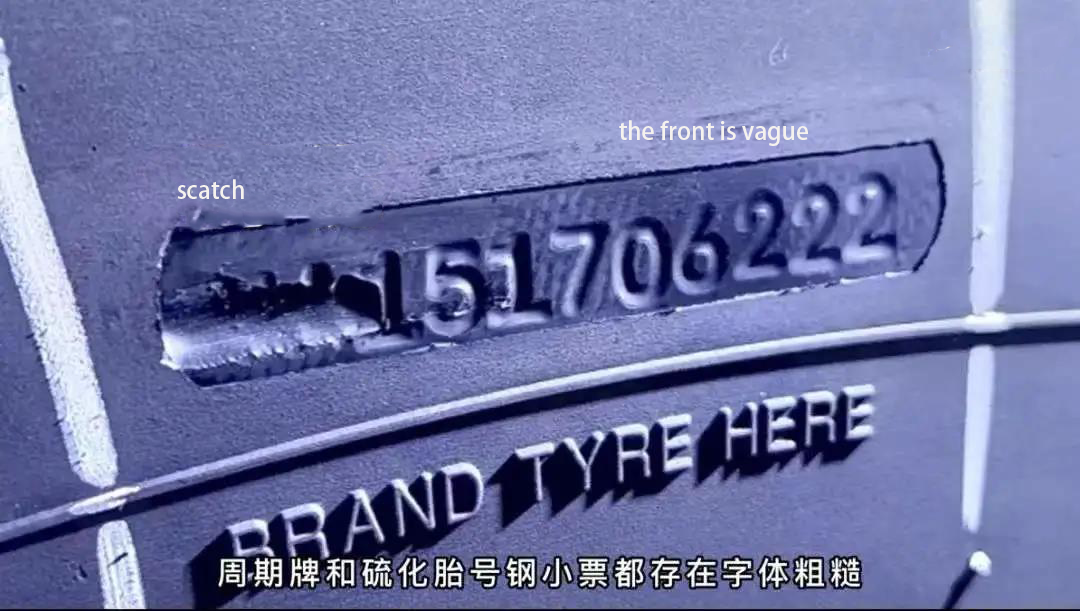

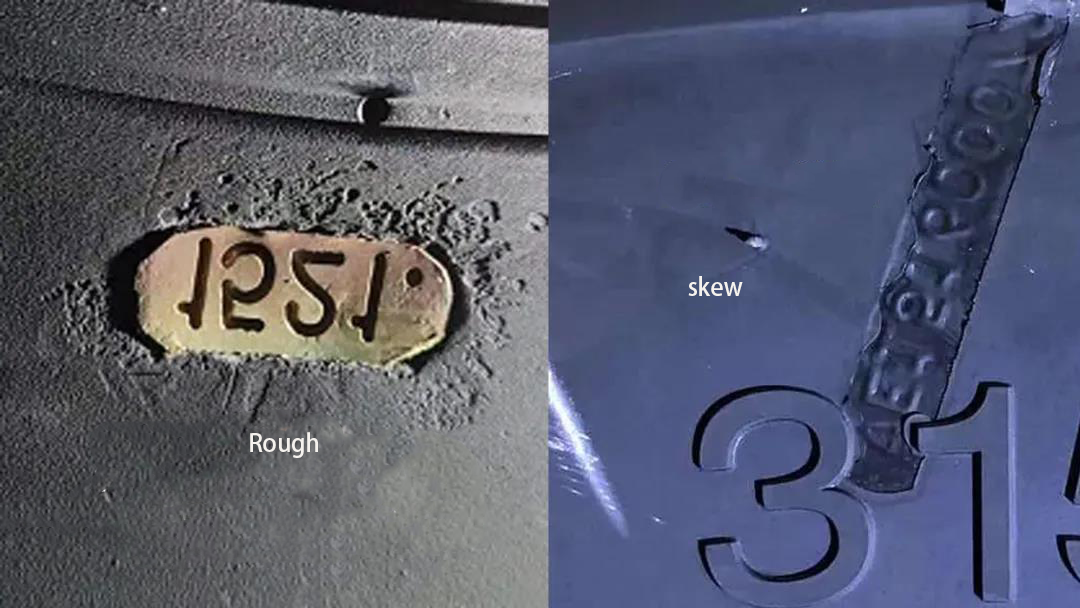

The traditional process of cycle plate and steel receipt is time-consuming and laborious, and the cost of consumables is high.Cycle brand needs to stop the replacement every week, easy to damage the mold in the process of operation, the installation position, the accuracy of rough gap rubber edge, the production of tire cycle brand uneven, rubber edge overflow, damage and flying, etc., seriously affect the appearance of the tire.

Tire laser engraving intelligent solution, eliminate the cycle brand overflow phenomenon, reduce the repair rate, improve the product phase;Completely bid farewell to the cycle plate, steel invoice process caused by the cost of materials, labor and error correction, improve the use rate of vulcanizing machine, achieve cost reduction and efficiency;It can automatically interact with the production MES system, automatically generate data, get through THE MES and WMS system, and improve the level of digitalization and intelligence.

Post time: Jan-11-2022