Meta Description: Explore the 2025 Q1 industrial robotics trends, including surging production, collaborative robots, welding automation breakthroughs, and China’s dominance in global exports.

Introduction: Industrial Robotics in 2025 Q1

The first quarter of 2025 has marked a pivotal phase for the global industrial robotics sector, driven by accelerating automation demands, advancements in collaborative robots (cobots), and breakthroughs in welding applications. China, the world’s largest robotics market, continues to lead in production and innovation, with domestic manufacturers expanding their global footprint. This article analyzes Q1 trends, supported by data, case studies, and projections for the year.

1. Surging Production and Market Growth

China’s industrial robotics output remains robust, with Q1 2025 production estimated to exceed 55,000 units, building on 2024’s annual output of 55.6 million units 3. Sales revenue is projected to surpass ¥900 billion ($124 billion) by year-end, fueled by automotive, electronics, and lithium battery manufacturing demand 17.

Key Drivers:

- · Automotive and EV Sector: Post-pandemic recovery in 3C electronics and rising electric vehicle (EV) production have driven SCARA and 6-axis robot adoption. SCARA robots, ideal for high-speed assembly, now account for 52.8% of lithium battery production lines 7.

- · Export Growth: Collaborative robot exports surged by 57.8% in 2024, with Chinese brands like AUBO and ELITE capturing 24.6% of global shipments 36.

2. Collaborative Robots (Cobots) Redefine Automation

Collaborative robots dominate Q1 innovations, blending safety and flexibility. For example, Zhengyin Technology’s CS-Robot-A16 (16kg payload) integrates AGV mobility and machine vision for automated quality testing, reducing human intervention in complex workflows 2.

Market Shift:

- · Domestic Dominance: Chinese cobot manufacturers now hold over 90% of the local market, outpacing foreign rivals in price competitiveness and customization 3.

- · Global Expansion: Companies like Unitree Robotics leverage AI advancements to reduce robot training time from 2 years to 1 month, accelerating deployments in Europe and North America 6.

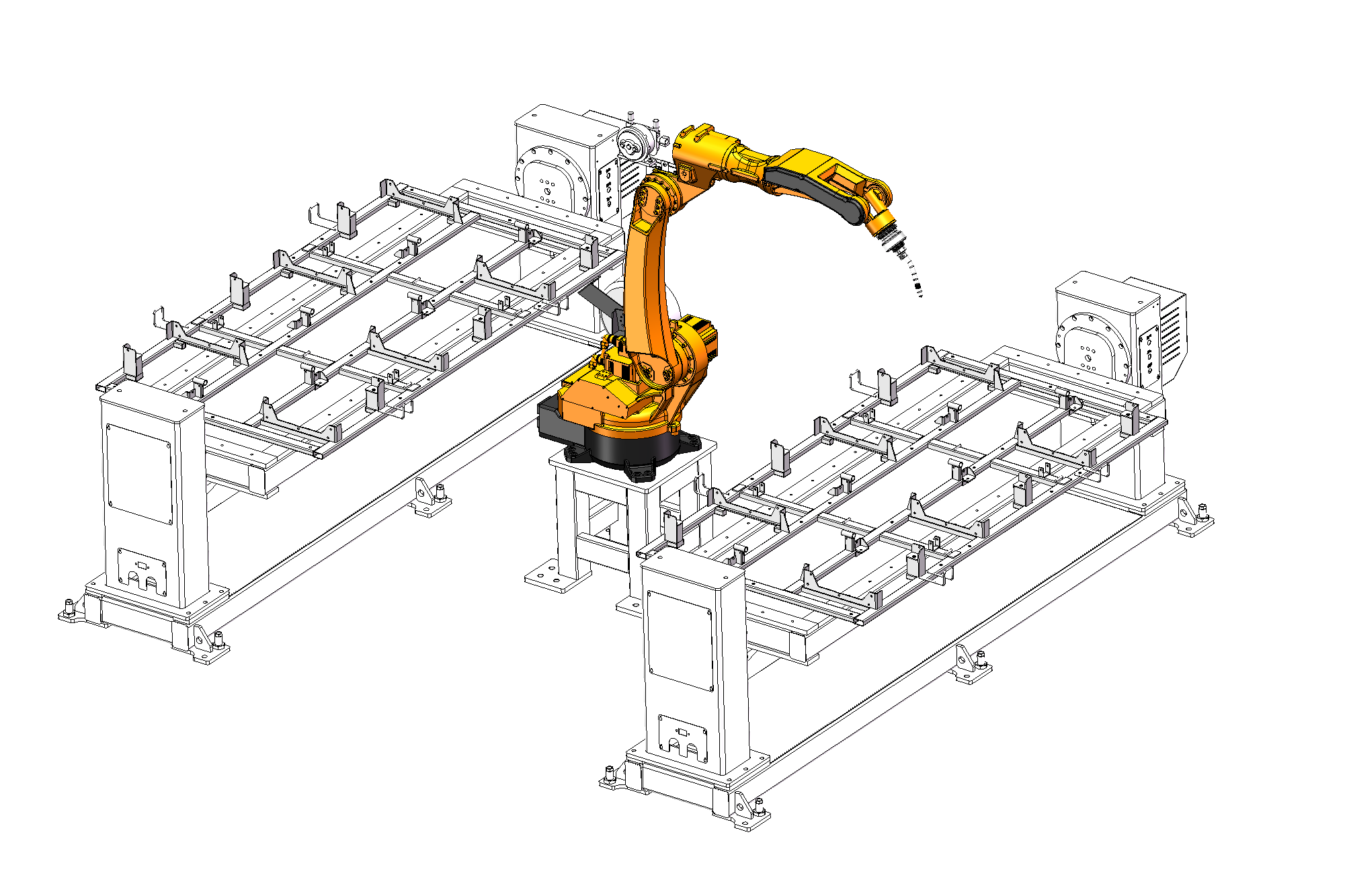

3. Welding Robotics: Precision and Efficiency

Industrial welding robots are experiencing unprecedented demand, driven by automotive and aerospace sectors. Made-in-China.com lists 87,959 welding robot models, including 6-axis laser welders and 9-axis systems for heavy-duty applications 8.

Case Study: Automated Arc Welding

The Raintech Arc Welding Robot Station (accuracy: ±0.5mm, speed: 2m/min) exemplifies Q1 trends with integrated vision systems and IoT connectivity, reducing defects by 30% in automotive chassis production 8.

4. Lithium Battery Manufacturing: A Growth Catalyst

The EV boom has turned lithium battery production into a robotics hotspot. GGII reports 6.7 million lithium battery robots will ship in 2025, with SCARA and 6-axis models handling tasks from electrode stacking to pack assembly 7.

Innovation Spotlight:

- · High-Payload SCARA: Models like the 50kg SCARA robot optimize battery module handling, reducing cycle times by 20% 7.

- · AI-Driven Quality Control: Systems combining cobots and AI vision detect microscopic defects in real time, ensuring 99.9% yield rates 6.

5. Challenges and 2025 Outlook

While growth is robust, challenges persist:

- · Price Wars: Domestic cobot manufacturers face profit margin pressures amid intense competition 3.

- · Supply Chain Bottlenecks: Customized components, such as harmonic drives, require agile suppliers in Guangdong and Jiangsu 6.

2025 Projections:

- · Global Leadership: China aims to supply 75% of the world’s collaborative robots by 2030 6.

- · AI Integration: Large language models (LLMs) like Baidu’s ERNIE Bot will enhance robotic decision-making in unstructured environments 9.

Visuals (Suggested)

- · Chart 1: 2023–2025 China Industrial Robot Production Growth (Source: GGII 3).

- · Image 1: CS-Robot-A16 in automated welding (Source: ColorSpace 2).

- · Image 2: Raintech Welding Robot with vision system (Source: Made-in-China 8).

Conclusion

The 2025 industrial robotics landscape is defined by China’s manufacturing prowess, cobot innovation, and welding automation breakthroughs. As AI and supply chain synergies deepen, manufacturers must prioritize R&D and global partnerships to sustain growth. Stay ahead with cutting-edge robotics solutions tailored for the automation era.

References

123

Post time: Mar-12-2025