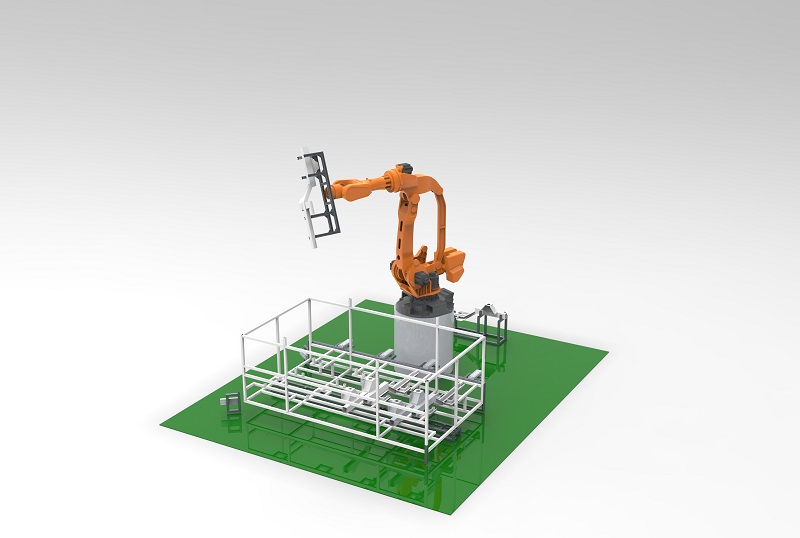

China’s welding robotics industry is set to make major strides in 2022. According to a recent survey conducted by the China Industrial Welding Alliance, over 40% of all welding robots used in Mainland China will be manufactured by Chinese brands by the end of next year. This number is expected to grow rapidly in the following years, with global companies such as ABB, Yaskawa and Kuka trailing behind local brands in terms of innovation and cost efficiency.

The survey also states that local brands have significantly improved their products and services in recent years, providing welding robots

with precise welding control and automated welding parameter selection. These robots are equipped with advanced vision sensors and digital integration that enable their users to monitor and trace changes in welding operations. Moreover, some of these robots are designed to reduce energy consumption, increase production speed and reduce downtime during maintenance.

The surge in the use of robotic welding systems is largely attributed to the continuous development of the industry and the increasingly stringent safety requirements set by regulatory agencies. In order to ensure high-quality welds and efficient production, manufacturers are investing in higher quality robots with advanced features such as intuitive monitoring and control systems, flexible programming options and secure data exchange protocols.

This increase in demand for Chinese welding robots is expected to boost the country’s overall robotics industry, creating new job opportunities and contributing to the local economy. With more and more companies turning to robots for welding automation, the future looks bright for China’s welding robotics industry.

Post time: Feb-06-2023