Megmeet Intelligent Digital Welding Machine

Megmeet Welder

Built In 2003

TOP 3 in China

Megmeet Profile

MEGMEET

Employee:

3200+

R&D Engineers:

650+

100+

Partners

200+

From Huawei&Emerson

12+

Classical Models

400+

Patents

8 R&D Centers

2 Manufacturing Bases

Lower Cost Means High Profit

- Saving with lower downtime. With the self-protecting design, power sources will display an error code on the meter. Once the errors are removed, the system will return to work as normal. Breakdowns and downtimes will be prevented.

- Saving with lower power consumption. Power consumption of 7 KWH is saved after welding every spoll of MIG wire, compared with the thyristor (SCR) welding machines.

- Saving with ability to meet various thickness. For different output current, welding performance is maintained at a satisfactory level.

- Saving with software updating of welding procedure specification. Once a new welding process is requested, end-users may upgrade the welding application software instead of investing into a totally new welding system.

- Saving thru welding quality control. With the locking-up function, on-site QC managers are able to prevent any unnecessary change of welding specification by welders. Inspection cost will be largely saved.

- Saving thru group control system. SMARC, the group control system, is able to link welding power sources of a large number to MES. Management cost will be largely saved thru monitoring the welding specification, thru data collecting and analysising.

Specification

| Manual | Ehave CM 500 H | Ehave CM 500 | Ehave CM 400 | Ehave CM 350 | Ehave CM 250 |

| Robotics | Ehave CM 500 H AR | Ehave CM 500 AR | Ehave CM 400 AR | Ehave CM 350 AR | Ehave CM 250 AR |

| Control Mode | Full Digital-Control | ||||

| Rated InputVoltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | ||||

| Input Frequency | 30 ~80 HZ | ||||

| Rated Input Power | 24 KVA | 22.3 KVA | 16.8 KVA | 13.5 KVA | 8 KVA |

| Power Factor | 0.93 | 0.93 | 0.94 | 0.94 | 0.94 |

| Efficiency | 86% | ||||

| Rated OCV | 75 V | 73.3V | 63.7V | 63.7V | 63.7V |

| Rated Output Current | 30~500A | 30~500A | 30~ 400A | 30~ 400A | 30~ 400A |

| Rated Output Voltage | 12~ 45V | 12~ 45V | 12 ~ 38V | 12 ~ 38V | 12 ~ 38V |

| Duty Cycle | 500A 100% @ 40°C | 500A 60% @40°C390A 100% @40°C | 400A 60% @40°C310A 100% @40°C | 350A 60% @40°C271A 100% @40°C | 250A 100% @40°C190A 100% @40°C |

| Applicable Material | Carbon Steel | ||||

| WeldingProcess | CO2 / MAG/FCAW / MMA | ||||

| Wire Diameter | φ1.0/ 1.2/ 1.6 mm | φ0.8/ 1.0/ 1.2 mm | |||

| WeldingOperationMode | 2T/ 4T/ Repeated 4T / Spot Welding | ||||

| ParameterChannel | 10 (Standard) | ||||

| Inductance Scope (Soft /Strong Arc) | -9~ +9 | ||||

| Communicationwith RobotController | Analog | ||||

| ReservedCommunicationInterface | CAN | ||||

| Cooling Mode | Intelligent Air Cool | ||||

| Wire feedingSpeed | 1.4 ~ 24 m/min | ||||

| ElectromagneticCompatibility | IEC60974:10 EMS | ||||

| InsulationGrade | H | ||||

| IngressProtection | IP23S | ||||

| ProtectionAgainstLightening | Class D (6000V/3000A) | ||||

| WorkingTemperature &Humidity | -39°C~ +50°C; Humidity ≤ 95%; | ||||

| Dimension(L/W/H) | 620x 300 x 480 mm | ||||

| Gross Weight | 52 KG | 52 KG | 48 KG | 48 KG | 48 KG |

| Manual | Artsen Plus 500 D/P/Q | Artsen Plus 400 D/P/Q | Artsen Plus 350 D/P/Q |

| Robotics | Artsen Plus 500 D/P/Q R | Artsen Plus 400 D/P/Q R | Artsen Plus 350 D/P/Q R |

| Control Mode | Full Digital-Control | ||

| Rated Input Voltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | AC3PH 380V +/-25%(3PH 250V ~ 3PH 475V)AC 3PH 220V +/-15%(3PH 187V ~ 3PH 254V) | |

| Input Frequency | 45 ~65 HZ | ||

| Rated Input Power | 24 KVA | 22.3 KVA | 16.8 KVA |

| Power Factor | 0.93 | ||

| Efficiency | 87% | ||

| Rated OCV | 85 V | ||

| Rated Output Current | 30~ 500 A | 30~ 500 A | 30~ 400 A |

| Rated Output Voltage | 12 ~ 45 V (Precision at 0.1V) | ||

| Duty Cycle | 500A / 39V 60% @ 40°C387A/ 33.5V 100% @ 40°C | 400A / 34V 100% @ 40°C | 350A / 33.5V 60% @ 40°C270A / 27.5V 100% @ 40°C |

| Applicable Material | D: Carbon Steel / Stainless SteelP: Carbon Steel / Stainless SteelQ: Carbon Steel / Stainless Steel / Aluminum Ally | ||

| Welding Process | D: MIG / MAG / CO2; Low- spatter;D: MIG / MAG / CO2; Low-spatter; Short-arc PulseQ: MIG / MAG / CO2;Low-spatter; Short-arc Pulse | ||

| Wire Diameter | φ0.8/0.9/ 1.0/ 1.2/ 1.6 mm | ||

| Welding Operation Mode | 2T/ 4T / Special 4T / Spot Welding / Leaping Welding | ||

| Inductance Scope (Soft /Strong Arc) | -7~ +7 | ||

| Push-pull Torch Function(1) | Yes | ||

| Communication with Robot Controller | Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNet/IP (2) | ||

| Digital Meter on Wire-feeder | Yes | ||

| Cooling Mode | Air Cool; Water Cool (Optional) | ||

| Electromagnetic Compatibility | IEC60974:10 EMS | ||

| Insulation Grade | H | ||

| Ingress Protection | IP 23S | ||

| Protection Against Lightening | Class D (6000V/3000A) | ||

| Working Temperature &Humidity | -39°C ~ +50°C; Humidity≤95%; | ||

| Dimension (L/W/H) | 620x 300 x 480 mm | ||

| Gross Weight | 52 KG | ||

| Manual | Artsen PM 500 F/N/AS/AD ll | Artsen CM 500 ll | Artsen PM 400 F/N/AS/AD ll | Artsen CM 400 ll |

| Robotics | Artsen PM 500 F/N/AS/AD R ll | Artsen CM 500 R ll | Artsen PM 400 F/N/AS/AD R ll | Artsen CM 400 R ll |

| Control Mode | Full Digital-Control | |||

| Rated Input Voltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | |||

| Input Frequency | 30 ~80 HZ | |||

| Rated Input Power | 24 KVA | 22.3 KVA | 19.7 KVA/ 18KW | 15 KVA/12.7KW |

| Power Factor | 0.93 | |||

| Efficiency | 87% | |||

| Rated OCV | 73.3 V | |||

| Rated Output Current | 30~ 500 A | 30~ 500 A | 30~ 400 A | 30~ 400 A |

| Rated Output Voltage | 12~45 V (Precision at 0.1V) | |||

| Duty Cycle | 500A 60% @ 40°C390A 100% @ 40°C | 500A 60% @ 40°C390A 100% @ 40°C | 400A 100% @ 40°C | 400A 100% @ 40°C |

| Applicable Material | F: Carbon SteelN:Carbon Steel / Stainless SteelAS/AD:Carbon Steel /Stainless Steel / Aluminum Alloy | Carbon Steel | F: Carbon SteelN:Carbon Steel / Stainless SteelAS/AD:Carbon Steel /Stainless Steel / Aluminum Alloy | Carbon Steel |

| Welding Process | VMIG/MAG/CO2Pulse MIG /MAGDouble Pulse MIG / MAG | MIG / MAG/ CO2 | MIG/MAG/CO2Pulse MIG /MAGDouble Pulse MIG/ MAG | MIG/ MAG/CO2 |

| Wire Diameter | φ0.8/ 1.0/ 1.2/ 1.6 mm | φ0.8/ 1.0/ 1.2 mm | ||

| Welding Operation Mode | 2T/ 4T / Special 4T / Spot Welding | |||

| Parameter Channel | 50 (Standard) | |||

| Inductance Scope (Soft /Strong Arc) | -9~ +9 | |||

| Push-pull Torch Function(1) | Yes | |||

| Communication with Robot Controller | Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNetIP (2) | |||

| Digital Meter on Wire-feeder | Yes | |||

| Cooling Mode | Air Cool; Water Cool (Optional) | |||

| Electromagnetic Compatibility | IEC60974:10 EMS | |||

| Insulation Grade | H | |||

| Ingress Protection | IP 23S | |||

| Protection Against Lightening | Class D (6000V/3000A) | |||

| Working Temperature &Humidity | -39°C ~ +50C; Humidity ≤ 95%; | |||

| Dimension (L/W/H) | 620x300x480mm | |||

| Gross Weight | 52KG | |||

| Artsen CM 500C | |

| Control Mode | Full Digital-Control |

| Carrier-Wave Communication | High-speed Two-way Digital Carrier-wave Communication |

| Rated Input Voltage | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) |

| Input Frequency | 30 ~80 HZ |

| Rated Input Power | 24 KVA |

| Power Factor | 0.93 |

| Efficiency | 86% |

| Rated OCV | 75V |

| Rated Output Current | 50~ 500 A |

| Rated Output Voltage | 12 ~ 50 V (Precision at 0.1V) |

| Duty Cycle | 500A / 39V 100% @ 40°C |

| Applicable Material | Carbon Steel |

| Welding Process | CO2/MAG/FCAW/MMA |

| Wire Diameter | φ1.0/ 1.2/ 1.4/ 1.6 mm |

| Welding Operation Mode | 2T / 4T / Special 4T |

| Parameter Channel | 10 (Standard) |

| Inductance Scope (Soft/ Strong Arc) | -9~ +9 |

| Reserved Communication Interface | CAN |

| Cooling Mode | Air Cool |

| Digital Meter on Wire- feeder | YES |

| Wire-feeding Speed | 1.4~ 24 m/min |

| Electromagnetic Compatibility | IEC60974:10 EMS |

| Ingress Protection | IP 23S |

| Insulation Grade | H |

| Protection Against Lightening | Class D (6000V/3000A) |

| Working Temperature | -39°C~ +50°C |

| Dimension (L/ W/ H) | 620x300x480mm |

| Gross Weight | 52 KG |

|

Manual |

Dex DM 3000 |

Dex DM 3000 S |

Dex PM 3000 |

Dex PM 3000 S |

|

Robotics |

- |

Dex DM 3000 R |

- |

Dex PM 3000 R |

|

Control Mode |

Full Digital-Control |

|||

|

Rated Input Voltage |

AC 3PH 380V -15%~ +21% (3PH 323V ~ 3PH 460V) |

|||

|

Input Frequency |

45 ~65 HZ |

|||

|

Rated Input Power |

9.2KVA/ 8.7 KW |

|||

|

Power Factor |

0.94 |

|||

|

Efficiency |

81% (210A/ 24.5V |

|||

|

Rated OCV |

54.2 V |

|||

|

Rated Output Current |

280 A |

|||

|

Output Current Range |

30A~ 300A |

|||

|

Rated Output Voltage |

12 ~ 30 V (Precision at 0.1V) |

|||

|

Duty Cycle |

280A/ 28V 60% @ 40°C 217A / 24.9V 100% @ 40°C |

|||

|

Applicable Material |

Carbon Steel / Stainless Steel |

Carbon Steel / Stainless Steel / Aluminum Alloy |

||

|

Welding Process |

MIG/MAG/CO2/MMA |

MIG/MAG/CO2/MMA Pulse MIG/MAG Double Pulse MIG/MAG |

||

|

Wire Diameter |

0.8/0.9/1.0/1.2 mm |

|||

|

Welding Operation Mode |

2T |

2T / 4T / Special 4T |

||

|

Parameter Channel |

50 (Standard)

|

|||

|

Inductance Scope (Soft /Strong Arc) |

-9~ +9 |

|||

|

Communication with Robot Controller |

- |

Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNet/IP

|

- |

Analog; DeviceNet; CAN Open; MEGMEET CAN; EtherNet/IP

|

|

Digital Meter on Wire-feeder |

- |

Yes |

- |

Yes Enclosed type with digital meters (A/ V) |

|

Cooling Mode |

Air Cool; Water Cool (Optional) |

|||

|

Wire-feeding Speed |

1.4 ~ 28 m/min |

|||

|

Electromagnetic Compatibility |

IEC60974:10 EMS |

|||

|

Insulation Grade |

H |

|||

|

Ingress Protection |

IP 23S |

|||

|

Protection Against Lightening |

Class D (6000V/3000A) |

|||

|

Working Temperature &Humidity |

-40°C ~ +70°C ; Humidity≤95%; |

|||

|

Dimension (L/W/H) |

610x260x398mm |

|||

|

Gross Weight |

25.4 KG |

23.7 KG |

25.4 KG |

23.7 KG |

User-friendly Design: convenient to use

Easy-to-Use Design for Unskilled Welders

- Built-in Function of Anti-shake

- On/Off Option of Synergi Control

- On/Off Option of Constant Penetration

Locking-up Function

- Without any external device, a locking-up password is able to be set up on the front panel. The requested welding specifications will be strictly prevented from unnecessary change. Management and inspection cost will be lowered, while welding quality will be ensured.

Quick Recovery of Production

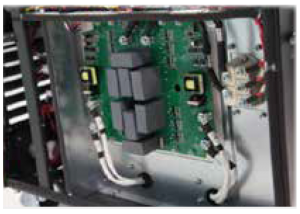

- The embedded structure and the modular design increase the reliability. Dismantling and re-assembly will be short in time consumption.

- The power source is designed to detect abnormality in the whole system. An error code will be displayed, but the power source won't be damaged.

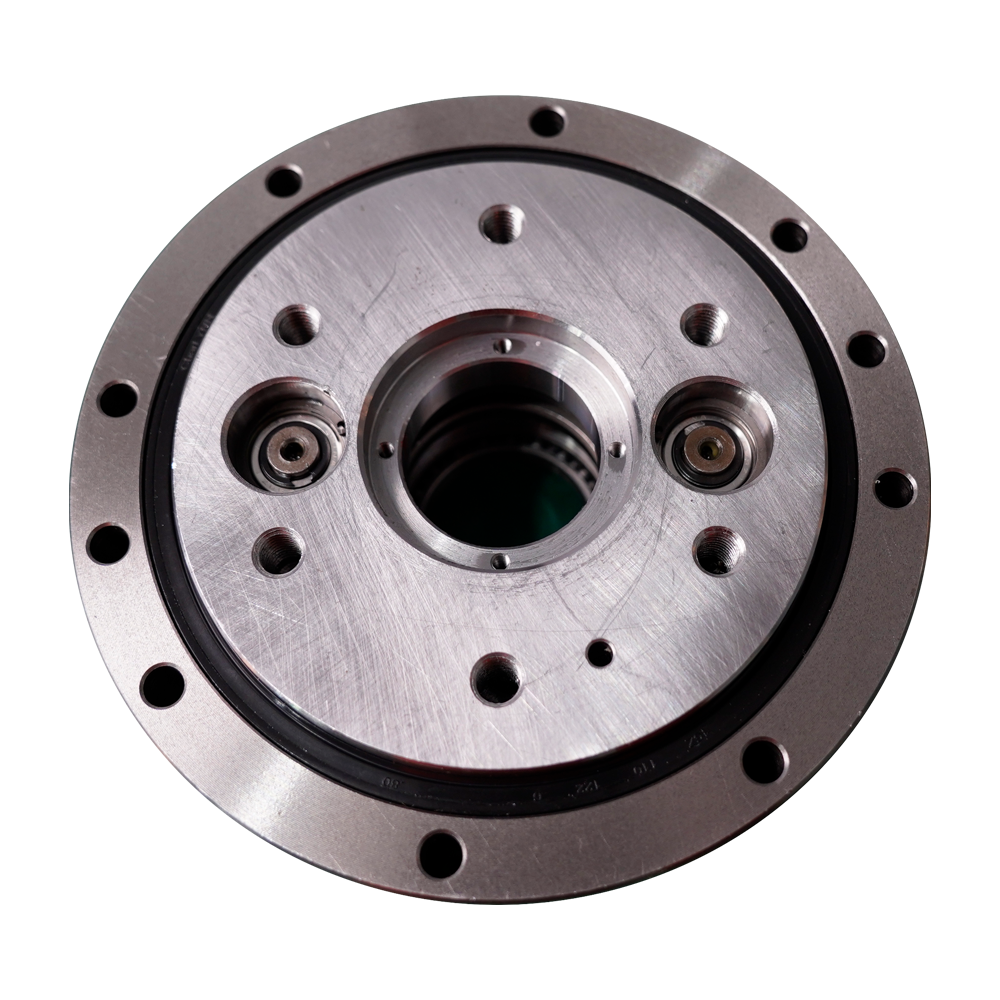

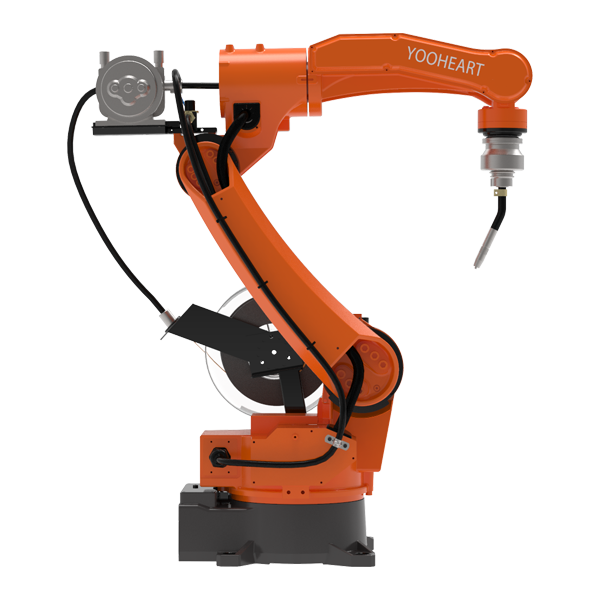

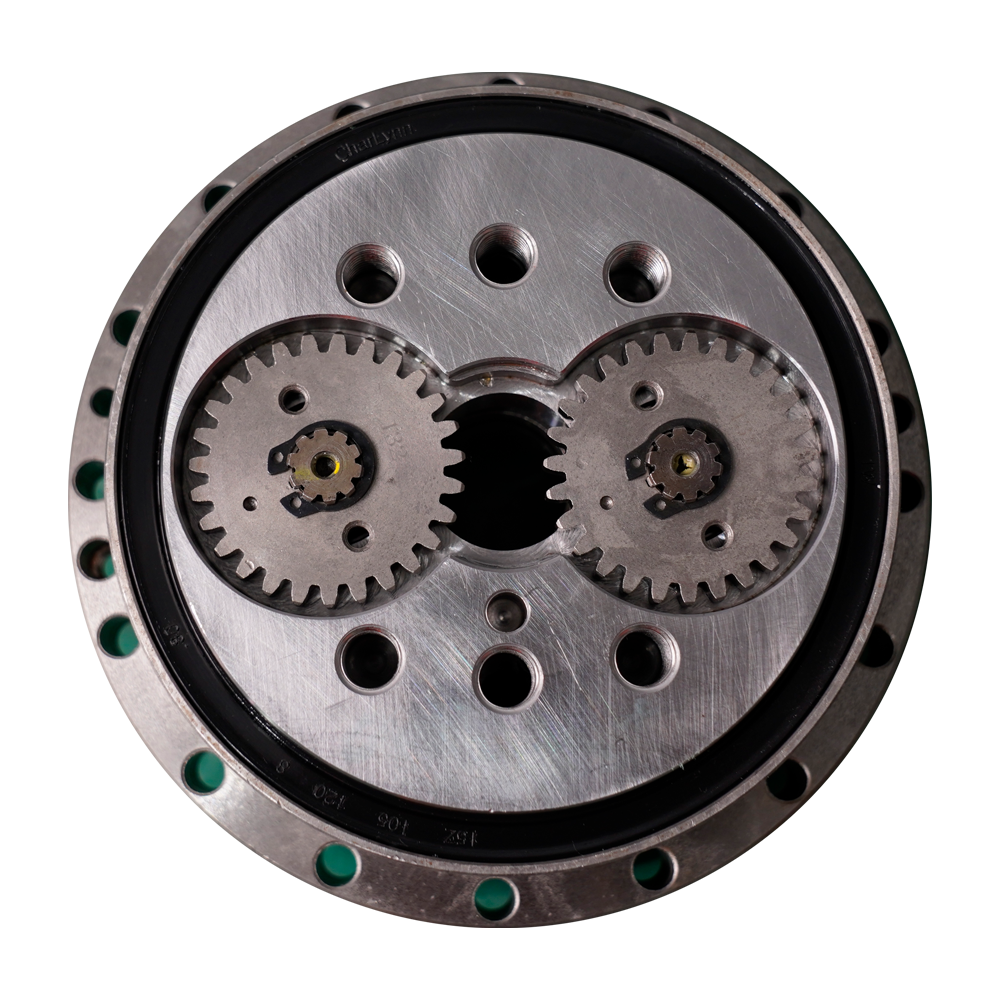

Robotic welder Appllications

Honyen Robot With Megmeet weld machine

Yooheart robot with Megmeet digital weld power source

Megmeet Customer