MAG-500Pro ASMT Welding Machine

1. Company Overview

Shandong Aotai Electric Co., Ltd., a national high-tech enterprise established in 1993, has been a pioneer in industrial welding and cutting solutions for over three decades. With state-owned capital holding 17.5% shares, the company operates three production bases in Jinan (93,000 m²), Zibo (166,000 m²), and Jining (10,000 m²), alongside global subsidiaries in the U.S., Russia, and India. Recognized for its inverter technology and innovation, Aotai has received multiple national awards, including the China Patent Excellence Award (2017) and National Science and Technology Progress Award (2004, 2016).

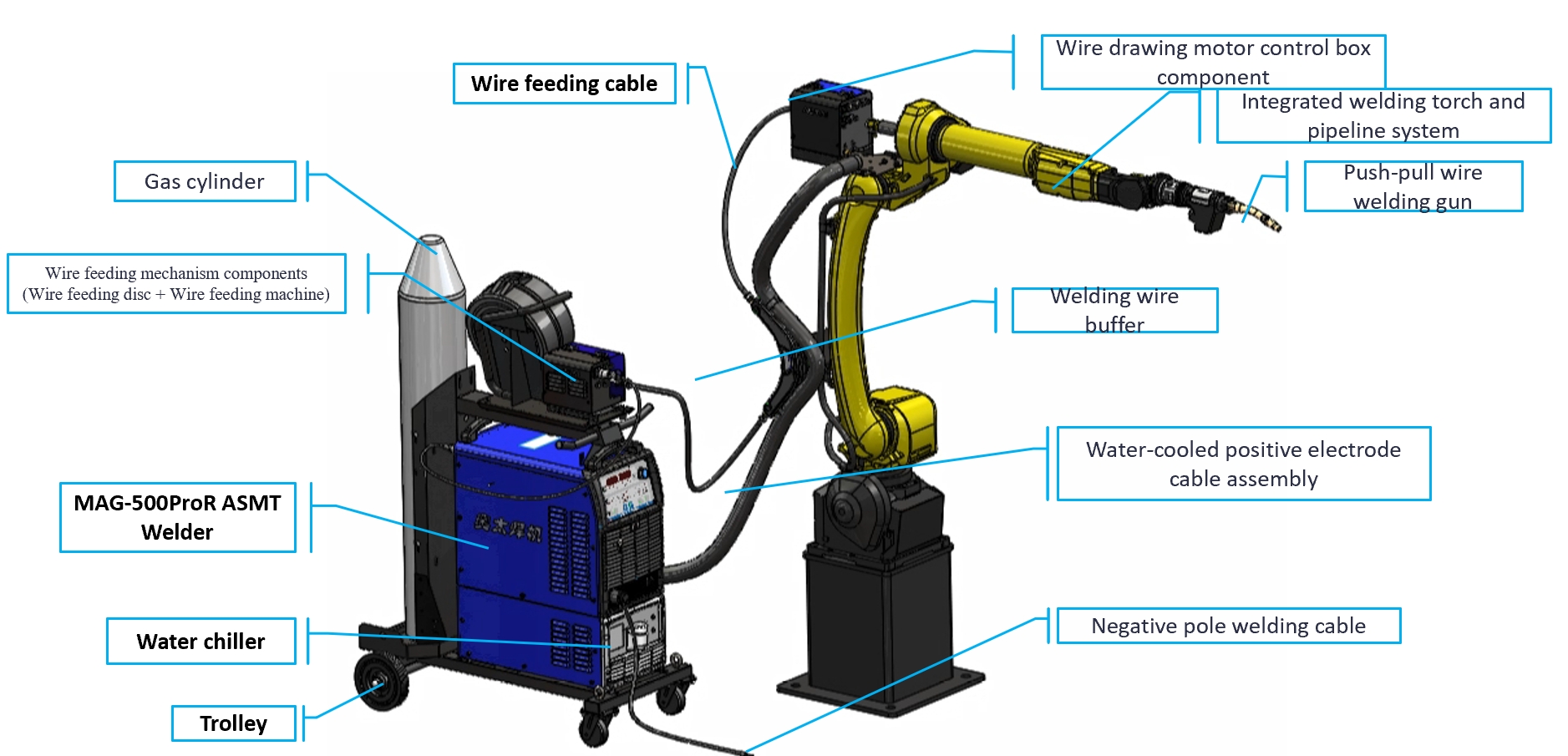

2. Product Overview: MAG500Pro ASMT Welding Machine

The MAG500Pro ASMT is a cutting-edge welding system designed for high-precision applications in industries such as new energy, automotive, nuclear power, and additive manufacturing. Equipped with ASMT (Temperature-Controlled Welding) and Pulse+ASMT Composite Process, it delivers spatter-free welds, superior gap bridging, and consistent penetration depth.

Key Materials Compatibility:

- Carbon steel

- Stainless steel

- Aluminum/copper alloys

3. Core Technologies

3.1 ASMT (Temperature-Controlled Welding)

ASMT synchronizes welding wire motion with current waveforms, enabling soft droplet transfer even at low currents. This technology stabilizes the arc, reduces heat input by 80%, and achieves 90% less spatter compared to conventional methods.

Advantages:

- 8x faster speed than TIG welding.

- Welds gaps up to 2mm in 2mm-thick aluminum.

- Minimal distortion and dilution rate.

3.2 Pulse+ASMT Composite Process

Combining ASMT short-circuit transfer and pulse phases, this hybrid process balances deep penetration with controlled heat input.

Advantages:

- Superior gap tolerance (2–4mm butt joints).

- TIG-like surface finish.

- Ideal for irregular gaps or varying thicknesses.

4. Technical Specifications & Features

| Parameter | Specification |

| Welding Modes | ASMT, Pulse, Pulse+ASMT, CMT |

| Max Welding Speed | 8x faster than TIG |

| Heat Input Reduction | Up to 80% (vs. TIG) |

| Spatter Reduction | 90% (vs. conventional pulse) |

| Material Thickness Range | 0.5–12mm (aluminum), 1–20mm (steel) |

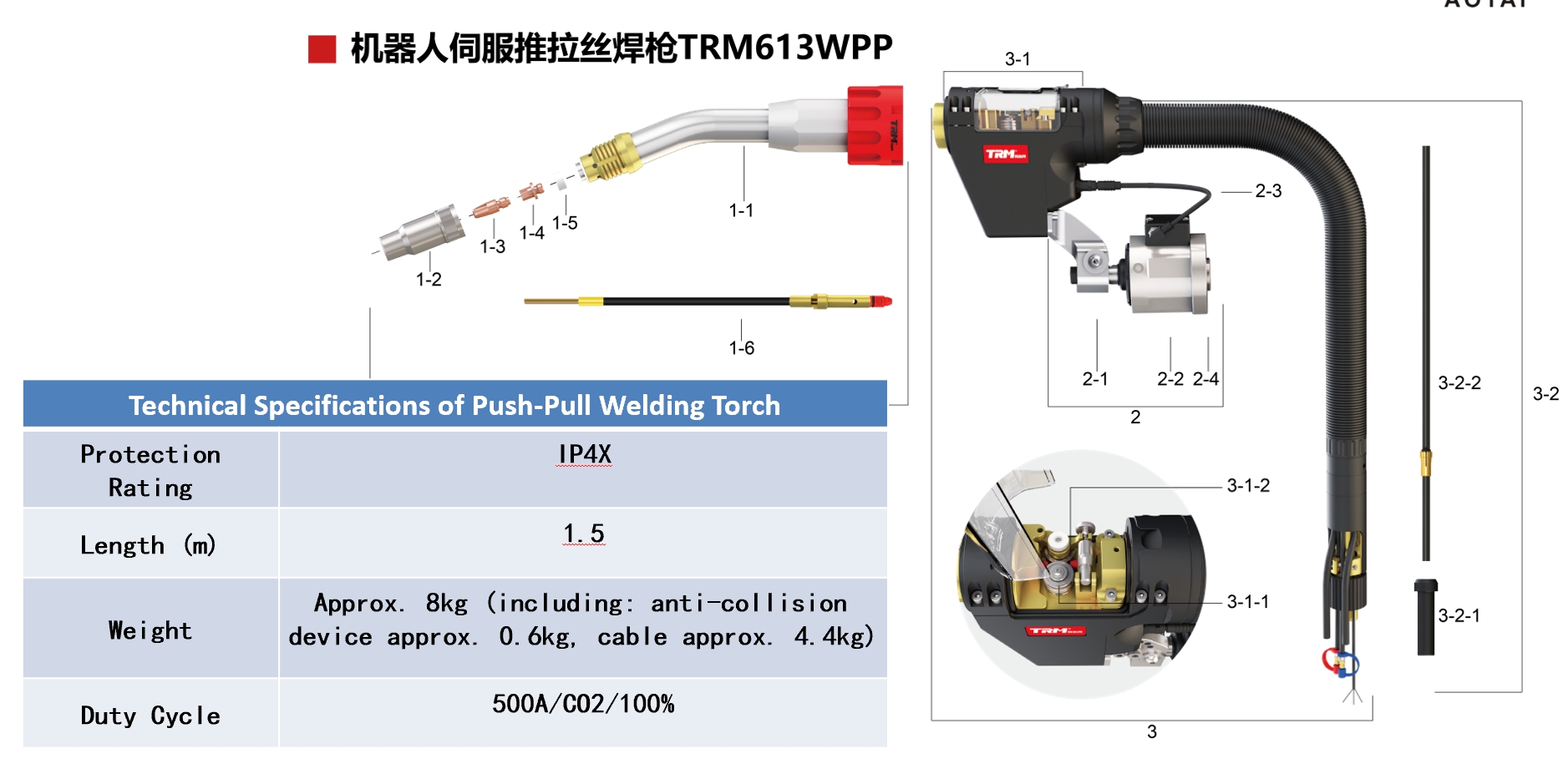

| Wire Feeding System | Servo-controlled push-pull mechanism |

| Voltage Compatibility | 380V ±25% |

| Optional Features | Cloud-based monitoring, water chiller |

5. Applications & Case Studies

5.1 New Energy Battery Trays

The MAG500Pro ASMT excels in welding aluminum alloy battery casings with near-zero spatter and low heat input. Its constant penetration depth control ensures uniform welds, critical for structural integrity.

Case Study: A leading EV manufacturer achieved 95% weld qualification rates using the Pulse+ASMT process for battery tray joints.

5.2 Automotive & Aerospace

The system’s CMT (Cold Metal Transfer) mode is ideal for thin sheets (e.g., car bodies or aircraft components), reducing distortion by 50%.

Case Study: A heavy-duty truck manufacturer replaced TIG with MAG500Pro ASMT for aluminum radiator welding, improving efficiency by 35%.

5.3 Additive Manufacturing

ASMT enables 3D printing of silicon bronze and aluminum alloys with precise layer-by-layer deposition.

6. Advantages Over Competing Technologies

| Feature | MAG500Pro ASMT | Traditional Pulse |

| Spatter | Near-zero | Moderate to high |

| Heat Input | 80% lower | High |

| Gap Bridging | Up to 2mm (aluminum) | ≤1mm |

| Speed | 8x faster (vs. TIG) | 2–3x slower |

| Application Flexibility | Thin sheets to thick plates | Limited to mid-range |

7. Integration with Plus Pulse Gas-Shielded Series

The MAG500Pro ASMT complements Aotai’s Plus Pulse Gas-Shielded Series, which offers:

- Fast Pulse Mode: 15–35% higher deposition efficiency for carbon/stainless steel.

- Deep Penetration Mode: 30% deeper penetration at 350A.

- Hybrid Wave Mode: Ideal for aluminum alloy fish-scale welds.

Synergy Benefits:

- Enhanced arc stability under 45m cable lengths.

- Cloud-based IoT integration for remote monitoring.

8. Conclusion

The MAG500Pro ASMT redefines precision welding with its ASMT and hybrid pulse technologies, offering unmatched speed, quality, and versatility. Backed by Aotai’s 30+ years of R&D expertise, it is the optimal choice for industries demanding high-performance welding solutions.