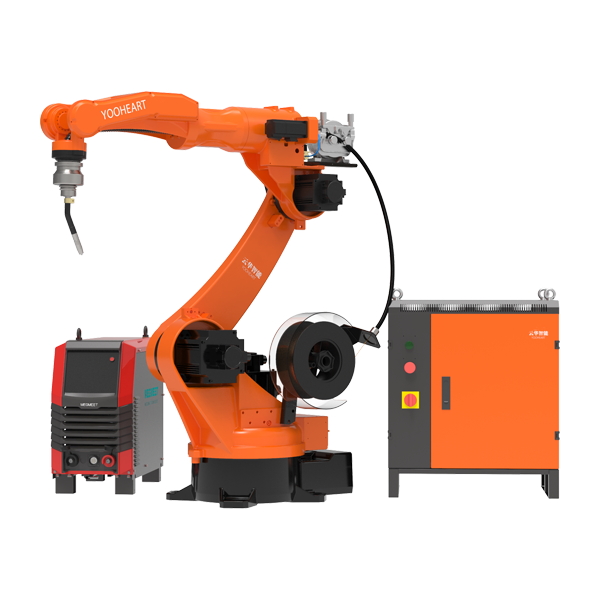

Industrial Robotic Welding Station

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We’re hunting forward to your check out for joint development for Industrial Robotic Welding Station, Our products and solutions are widely recognized and reliable by users and can meet continuously changing economic and social needs.

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We’re hunting forward to your check out for joint development for Welding Arm Robot and 6kg Welding Arm Robot, Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

DELIVERY AND SHIPMENT

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOOHEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOO HEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in YOO HEART factory. There will be a wechat group or whatsapp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc. will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.How many external axis can YOO HEART robot add?

A.At present, YOO HEART robot can add 3 more external axis to robot which can collaborate with robot. That is to say, we have standard robot work station with 7 axis, 8 axis and 9 axis.

Q2. If we want to add more axis to the robot, is there any choice?

A. Do you know PLC? If you know this, our robot can communicate with PLC, and then give signals to PLC to control external axis. In this way, you can add 10 or more external axis. The only shortage of this way is that the external axis can’t collaborate with robot.

Q3. How PLC communicate with robot?

A. We have i/O board in the control cabinet, there are 22 output port and 22 input port, PLC will connect I/O board and receive signals from robot.

Q4. Can we add more I/o port?

A. For simply weld application, these I/O port is enough, if you need more, we have I/O expanding board. You can add another 22 input and output.

Q5. What kind of PLC do you use?

A. Now we can connect Mitsubishi and Siemens and also some other brands.In the ever-evolving landscape of industrial automation, the YH1010A-150 welding robot stands out as a versatile and efficient solution for a wide range of welding applications. Manufactured by Anhui Yunhua Intelligent Equipment Co., Ltd., a leading technology enterprise in China specializing in industrial robots, this welding robot combines precision, power, and advanced technology to meet the demanding needs of modern manufacturing.

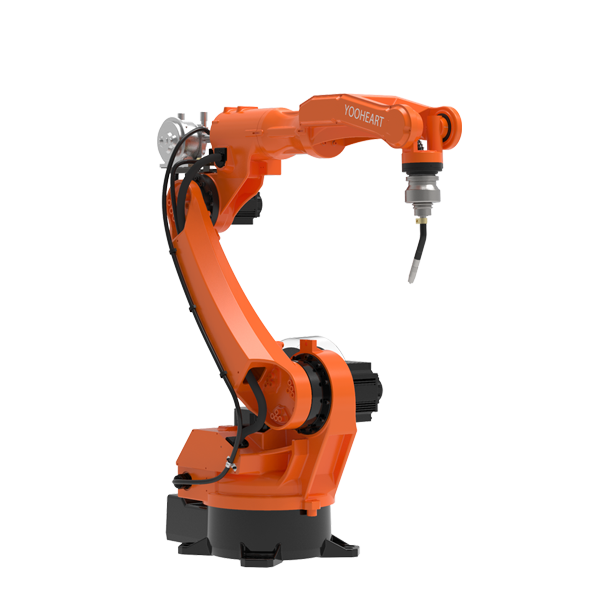

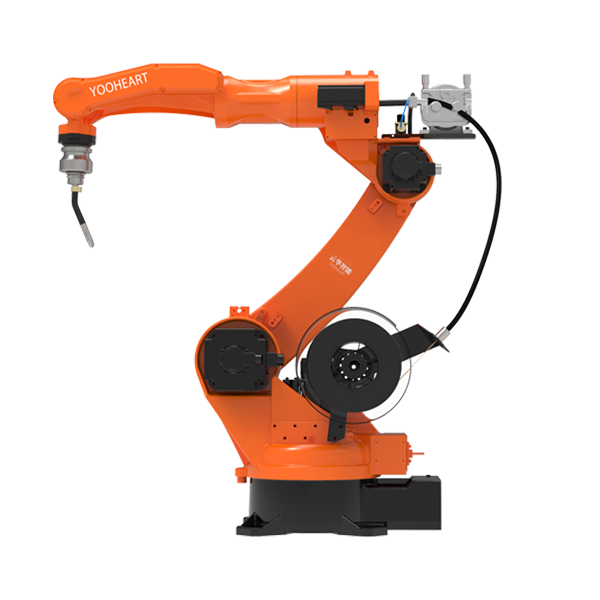

The YH1010A-150 welding robot is designed for high-performance welding tasks, offering a working range of 1500mm and a maximum load capacity of 10kg. With a robust body weighing 180kg, this robot can be installed either on the ground or ceiling-mounted, providing flexibility in workspace layout. Its six joints, driven by servo motors, enable precise and rapid movements in three-dimensional space, ensuring accurate welding of complex structures.

One of the key features of the YH1010A-150 is its high-precision laser welding capability. Before welding, the robot precisely positions the workpiece according to a preset program, ensuring optimal welding positions. The laser beam, focused on the welding area, rapidly melts the material as it moves along a predetermined path, creating continuous or spot welds. Advanced sensors, such as weld seam tracking devices and vision systems, monitor the welding process in real-time, adjusting the laser focus and welding trajectory to compensate for workpiece variations and mechanical errors.

The robot’s control system continuously records and analyzes welding data, optimizing process parameters through machine learning, thereby enhancing welding efficiency and product quality. Post-welding, the molten pool cools naturally, forming a strong weld joint, which may undergo subsequent stress relief treatment and inspection.

The YH1010A-150 welding robot is equipped with a user-friendly human-machine interface (HMI), allowing operators to set and monitor welding programs, view real-time data, adjust parameters, and receive fault alerts via a touchscreen or other visual operation panels.

This welding robot finds extensive applications in various industries, including automotive manufacturing, aerospace, electronics, medical device production, and more. Its high welding speed, precision, and minimal deformation make it ideal for joining materials with different thicknesses and compositions. Additionally, its automation capabilities and integration with intelligent systems adapt it seamlessly to smart production lines.

In conclusion, the YH1010A-150 welding robot represents the pinnacle of welding technology, combining efficiency, accuracy, and versatility. Its advanced features and robust design make it a valuable asset for any manufacturing facility seeking to enhance productivity and焊接quality.