Watch Us in Action!

Famous Model Following

TIG welding Power source, Manual&Robot model, Support different communication protocal

WSME 315/400/500/630

Inverted AC and DC pulse argon arc welding machine

Functions:

AC constant current TIG, AC pulse TIG, DC constant current TIG, AC pulse TIG, manual mental-arc welding.

Application industry:

Aerospace, space division, petrochemical industry, heat exchanger, aluminum furniture and bicycle light.

Features:

The operation panel with reasonable layout, rich functions and convenient operation;

◆The welding parameter can be preset precisely;

◆The AC frequency and cleaning width can be adjusted independently to meet the needs of welding process for different aluminium products;

◆It has easy arc strike, stable electric arc and easily controlled weld pool;

◆The argon arc welding can protect the welding gun from water depletion;

◆The welding current can be controlled afar;

◆The weld penetration and weld width required by the weld joint and the number of waveform can be obtained through the adjustment of the pulse current, impulse frequency, duty ratio, alternating current, AC frequency, cleaning proportion and AC bias ratio when the AC argon arc welding is used to prolong the service life, specially applicable to the automatic welding and robot welding.

| Model | WSME- -315R | WSME-400 | WSME- 500 | WSME-630 |

| Rated input voltage /frequency | Three-phase380V(+/-)10% 50Hz | |||

| Rated input capacity (KVA) | 12.1 | 17.1 | 25.7 | 34.7 |

| Rated input current (A) | 18.5 | 26 | 39 | 53 |

| Rated load sustainability (%) | 60 | 60 | 60 | 60 |

| Output no-load voltage (V) | 63 | 70 | 79 | 79 |

| Output current range (A) | 5~315 | 5~400 | 20~500 | 20-630 |

| Arc starting current (A) | 10~315 | 10~400 | 20~500 | 20-630 |

| Peak current (A) | 5~315 | 10~400 | 20~500 | 20-630 |

| Arc stopping current (A) | 5~315 | 10~400 | 20~500 | 20-630 |

| Pre - flow time (S) | 0.1~15 | |||

| Lagging time of gas-stopping (S) | 0.1~20 | |||

| Pulse frequency (Hz) | 0.2~20 | |||

| Pulse duty (%) | 1~100% | |||

| AC frequency (Hz) | 20~200 | 20~200 | 20~100 | 20~100 |

| TIG pilot arc style | HF arc | |||

| Thrust current (A) | 30-315 | 50-400 | 50-500 | 50-630 |

| Cooling mode | Water cooling | |||

| Insulation grade | H/B | |||

WSM 315/400/500

Inverted DC pulse argon arc welding machine

Functions:

DC constant current TIG, DC pulse TIG, manual metal-arc welding.

Application industry:

Petrochemical industry, pressure vessel, electric power construction, vessel, bicycle, nuclear power and pipe laying.

Features:

◆The operation panel with reasonable layout, rich functions and convenient operation;

◆Parameters such as the slow rise and slow descent of electric current, impulse frequency, duty ratio, the time of advanced gas supply and lagged gas supply can be preset precisely;

◆The manual metal-arc welding can adjust the electric current of the arc striking and thrust, with an easier striking of arc and preventing the adhesion of welding rod;

◆The argon arc welding can protect the welding gun from water depletion;

◆It has two-step and four-step welding control modes;

◆It is smaller and lighter and convenient for movement;

◆The current and the voltage can be displayed simultaneously. The welding current can be preset precisely;

◆TIG can choose the way of the high frequency lifting of arc striking.

| Model | WSM-315 | WSM-400 | WSM- 500 | ||

| Rated input voltage/frequency | Three- phase380V(+/-)10% 50Hz | ||||

| Rated input capacity (KVA) | 11.2 | 17.1 | 23.7 | ||

| Rated input current (A) | 17 | 26 | 36 | ||

| Rated load sustainability (%) | 60 | 60 | 60 | ||

| DC constant current Welding current (A) | 5~315 | 5~400 | 5~500 | ||

| DC pulse | Peak current (A) | 5~315 | 5~400 | 5~500 | |

| Base current (A) | 5~315 | 5~400 | 5~500 | ||

| Pulse duty (%) | 1~100 | ||||

| Pulse frequency (Hz) | 0.2~20 | ||||

| TIG | Arc starting current (A) | 10~160 | |||

| Arc stopping current (A) | 5~315 | 5~400 | 5-500 | ||

| Pre-flow time (S) | 0.1-15 | ||||

| Lagging time of gas- -stopping (S) | 0.1~20 | ||||

| TIG pilot arc style | HF arc | ||||

| Hand arc welding Welding current (A) | 30~315 | 40~400 | 50~500 | ||

| Cooling mode | Water cooling / Air cooling | ||||

| Shell protection grade | IP21S | ||||

| Insulation grade | H/B | ||||

WSM -S/YS 400

Inverted DC pulse argon arc welding machine

| Model | WSM-400S/YS | ||

| Rated input voltage/frequency | Three- phase380V(+/-)10% 50Hz | ||

| Rated input capacity (KVA) | 17.1 | ||

| Rated input current (A) | 26 | ||

| Rated load sustainability (%) | 60 | ||

| DC constant current Welding current (A) | 5~400 | ||

| DC pulse | Peak current (A) | 5~400 | |

| Base current (A) | 5~400 | ||

| Pulse duty (%) | 1~100 | ||

| Pulse frequency (Hz) | 0.2~20 | ||

| Pre-flow time (S) | 0.1-15 | ||

| Lagging time of gas- -stopping (S) | 0.1~20 | ||

| Working style of arc stopping current | Two-step、Four-step | ||

| TIG pilot arc style | HF arc | ||

| Cooling mode | Water cooling / Air cooling | ||

| Shell protection grade | IP21S | ||

| Insulation grade | H/B | ||

Functions:

DC constant current TIG, DC pulse TIG.

Application industry:

Petrochemical industry, pressure vessel, electric power construction, vessel, bicycle, nuclear power and pipe laying.

Features:

◆The operation panel with reasonable layout, rich functions and convenient operation;

◆Parameters such as the slow rise and slow descent of electric current, impulse frequency, duty ratio, the time of advanced gas supply and lagged gas supply can be preset precisely;

◆The manual metal-arc welding can adjust the electric current of the arc striking and thrust, with an easier striking of arc and preventing the adhesion of welding rod;

◆The argon arc welding can protect the welding gun from water depletion;

◆It has two-step and four-step welding control modes; It is smaller and lighter and convenient for movement;

◆The current and the voltage can be displayed simultaneously. The welding current can be preset precisely;

◆TIG can choose the way of the high frequency lifting of arc striking;

◆The built-in strong wire feed system has a rich function menus of wire feeding, which can meet different process requirement;

◆The wire feed rate and pulse current match automatically.

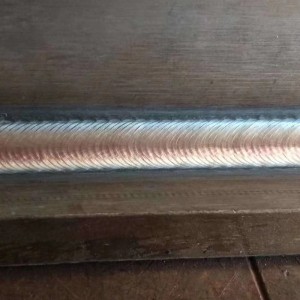

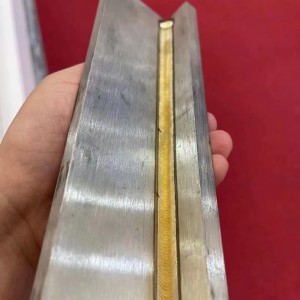

Consideration of Welder

When two steel plates with different thicknesses are butted together, in order to avoid serious stress concentration caused by the rapid change of the cross-section, the edge of the thicker plate is often gradually thinned to achieve the same thickness at the two edges. The static and fatigue strength of butt joints are higher than other joints. For connections under alternating, shock loads or working in low temperature and high pressure vessels, welding of butt joints is often preferred. The pre-welding preparation of the lap joint is simple, the assembly is convenient, and the welding deformation and residual stress are small, so it is often used in the installation of joints and unimportant structures on site. In general, lap joints are not suitable for working under conditions such as alternating loads, corrosive media, high or low temperatures. The use of T-joints and corner joints is usually due to structural needs. The working characteristics of incomplete fillet welds on T-joints are similar to fillet welds on lap joints. When the weld is perpendicular to the direction of the external force, it becomes a front fillet weld. At this time, the shape of the weld surface will cause different degrees of stress concentration; the stress of the penetration fillet weld is similar to that of the butt joint.

Why Choose us

WE’RE CREATIVE

BINGO continuously researches and develops intelligent welding technology let more welding equipment go global

WE’RE PASSIONATE

Now it has been affected and favored by many countries in the future

WE’RE AWESOME

We will invest more resources in continuous r & d and production go forward never stop