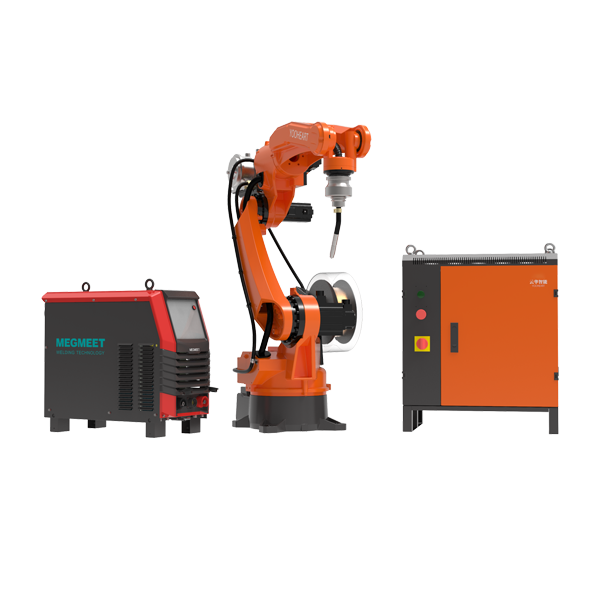

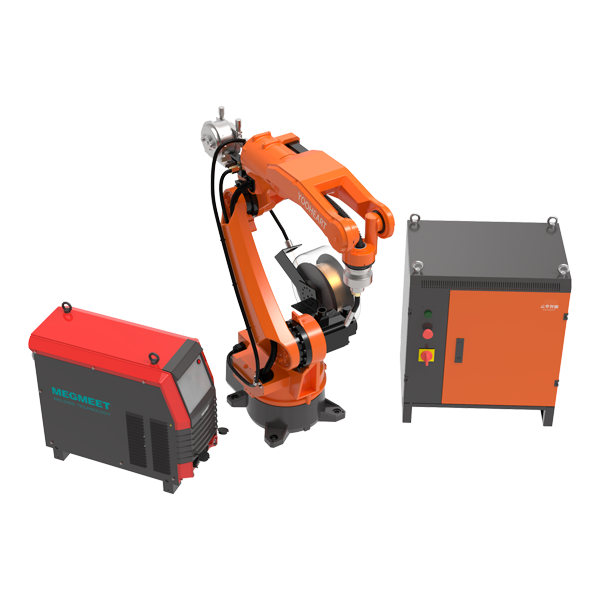

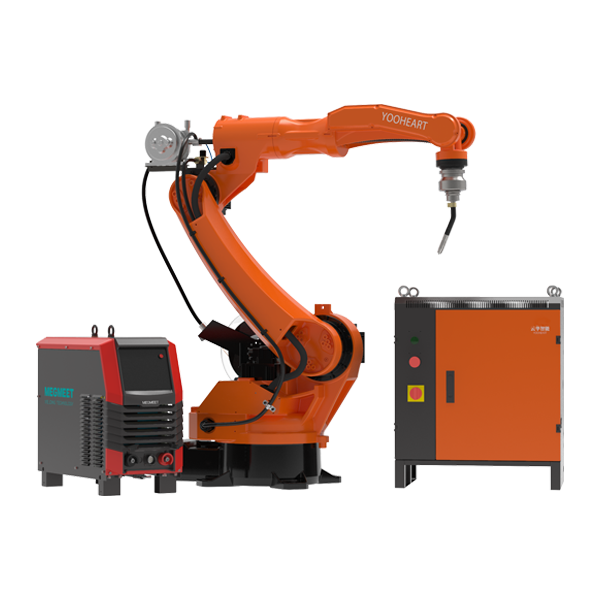

6 Axis Arc welding Robot 1450mm arm length With Megmeet welding power source

-Robot body: HY1006A-145

-Weld power source: Megmeet Ehave CM 350AR

-Welding Torch: Loyee gas cooling torch Or Honyen Gas cooling torch

-Wire feeder with 0.8/1.0 wire roller

-LNC controller and Panel

-Wooden Packing for exporting

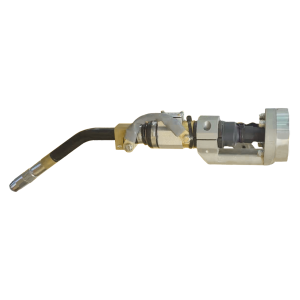

Optional Welding Torch

Loyee Robot Welding Torch

High torque and wear resistance cable

Invention patent of Anti-collision technology

High speed and precision repositioning of anti-collision device\

Wire Dia:0.8~1.0mm

Honyen Robot Welding Torch

High torque and wear resistance cable

Invention patent of Anti-collision technology

High speed and precision repositioning of anti-collision device

Wire Dia:0.8~1.0mm

Other Configuration Equipment

Megmeet Ehave CM 350AR

| item | Specification |

| Model | Megmeet Ehave CM 350 |

| Voltage | 3*380V±25% 30--80HZ |

| Rated Input Power | 13.5KVA |

| Power Factor | 0.94 |

| Efficiency | 86% |

| Rated OCV | 63.3V |

| Rated Output Current | 30A-400A |

| Rated Output Voltage | 12V-38V |

| Wire Dia | 0.8mm/1.0mm/1.2mm |

| IP Level | IP23S |

| Insulation Grade | H |

| Cooling Mode | Air Cooling |

| Dimension

(L*W*H) |

620mm*300mm*480mm |

| Weight | 48kg |

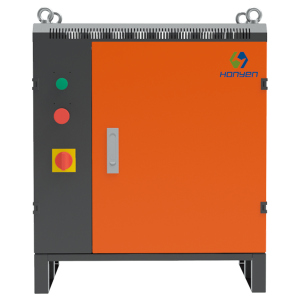

Control Cabinet

| Item | Specification |

| Cabinet Size | 603mm*502mm*760mm |

| Weight | 55kg |

| IP Level | IP54/IP65 |

| Temperature | Working:0-45℃Storage:-10~60℃ |

| Humidity | Max 90%(No-condensation |

| Voltage | 3*380V 50~60HZ |

| Cooling System | Fan Cooling |

| Cable Length | Standard: 5M, Max:12M |

| Communication Mode | Pulse |

Wire feeder

Timely Response Wire feeding and back

Smoothly wire feeding, No-accumulation and Slipping

Strong Anti-interference Capacity

Customer's Application

Baby Carriage Robot Working Station

Steel Ladder Robot Working Station

Pictures At Customer's Factory

Welding Robot Parameters

| Axis | Payload | Repeatability | Power capacity | Environment | Weight | Installation |

| 6 | 6kg | 0.08 | 6.5KVA | 0~45℃ 20~80%RH(No Condensation) |

170kg | Ground/Ceiling |

| Motion Range J1 | J2 | J3 | J4 | J5 | J6 | IP level |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65(wrist) |

| Max speed J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

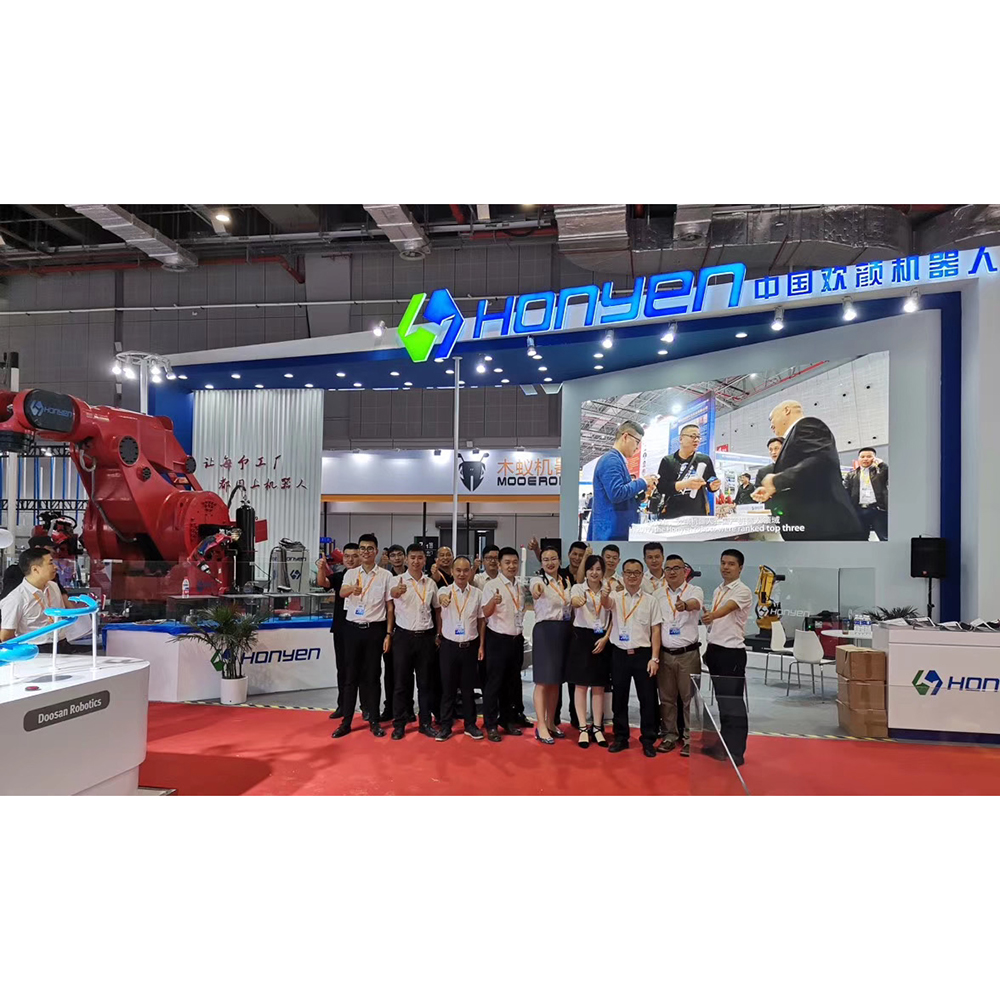

Exibitions

Beijing Essen Welding & Cutting Fair

China International Industry Fair – CIIF

China International Machine Tool Show

FQA

Q. What is the key market of your robot?

A. Now our robot can service for automotive, steel structure, farm machine, steel furniture, new energy, storage and delivery, engineering machine, physical equipment, animal machine, motor bike etc.

Q.what kind of service can you offer?

A. As for applications, welding, handing, pick and place, painting, palletizing, laser cutting, laser welding, plasma cutting and so on.

Q. What kind of welding process do you have?

A. For welding applications, we can offer argon arc welding, mag welding, gas shield welding, tig self fusion welding, tig wire feeding welding.

Q. What is the brand of power source you offer for robot?

A. Now for standard configuration: Megmeet and AoTai.

Q. Do you have your own control system?

A. Yes, of course we have. Not only we have control system, the most important parts of robot: reducer is being produced. That is why we have the most competitive price.

After sales Service

The product quality guarantee period is one year from the date of delivery. If welding robot fails during the warranty period (except for the failure caused by improper use by the buyer), Honyen Robot shall be responsible for maintenance until replacing the new equipment(EXW), and the expenses incurred shall be borne by Honyen(delivery cost is not included); In case of equipment failure caused by improper use of the buyer, Honyen factory shall be responsible for maintenance and charge for replacement parts.

During the warranty period, in case of equipment failure, the seller's technical service personnel shall prepare necessary tools and spare parts within 8 hours after confirming the equipment failure with the on-site operation and maintenance personnel, and arrive at the site within 24 hours and start maintenance, troubleshooting (except for the reason of distance).

Every year, based on the actual market situation and the needs of regional users, the company regularly carries out regional technical service return visits free of charge (excluding the service fee for replacing parts and components).

Corresponding to the products sold by our company and the conventional parts and consumable parts of the complete set of welding robot, we guarantee to provide conventional services. The spare parts are in the warehouse (except for special products). The conventional parts and consumable parts are guaranteed to be supplied in time according to the order, and the special parts are ordered according to the contract agreed by both parties.

After the expiration of the warranty period, if the equipment fails, the Seller shall continue to provide maintenance services for the buyer, charge the cost of replacing accessories, and charge the basic service fee for door-to-door service.

According to the buyer's demand, the Seller shall be responsible for the lifelong free upgrade of the equipment software used by the buyer for Mig welding robot