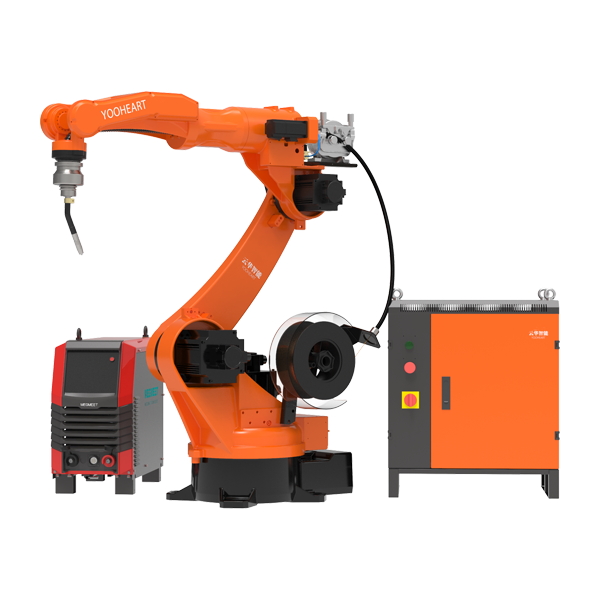

6 axis Mig welding robot for storage rack

Product Introduction

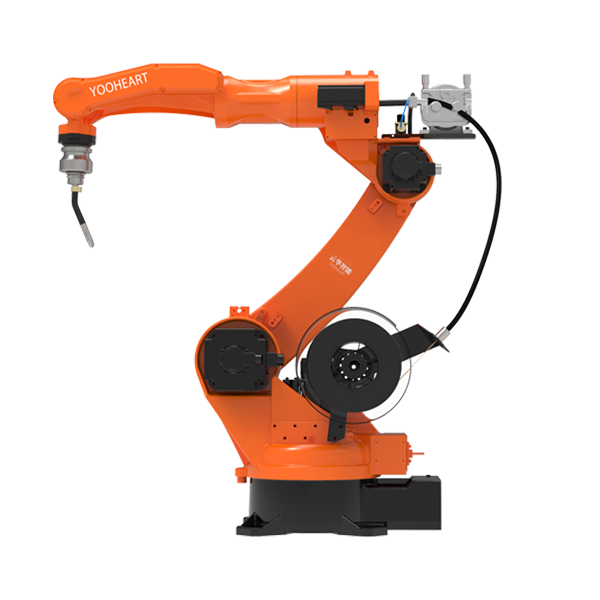

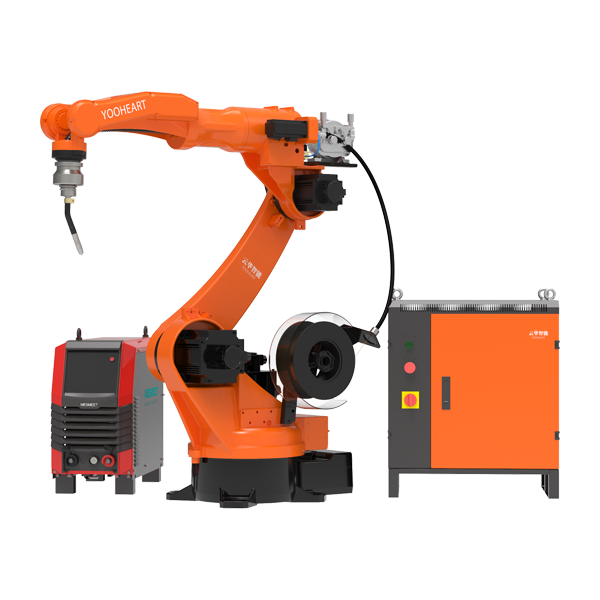

The six axis welding robot is one of the typical robot of Yooheart product. As you know, over 50% of material needed to weld is carbon steel, so in order to weld carbon steel better, there are a lot of special designs for the six axis robot. There are over 5000 units was sold in China per year because of its stability and durability.

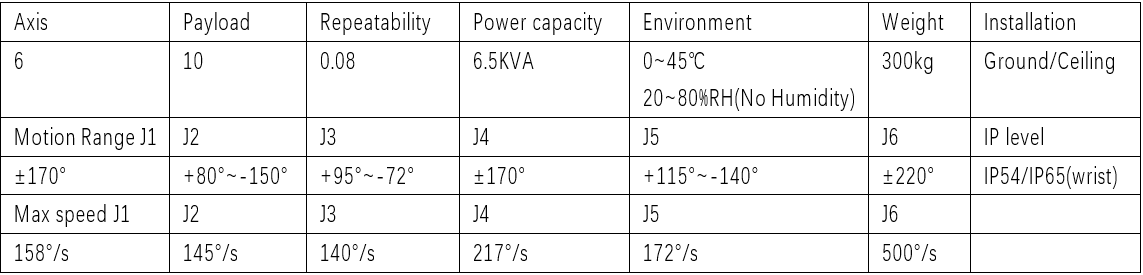

PRODUCT PARAMETER& DETAILS

As one of the popular industrial welding robot, it has streamline arm with min interference and max flexibility, the welding current voltage and wire feeding can be controlled at real-time. The welding parameters of the welding line can be set directly on the teaching pendant of the robot.

Application

FIGURE 1

Introduction

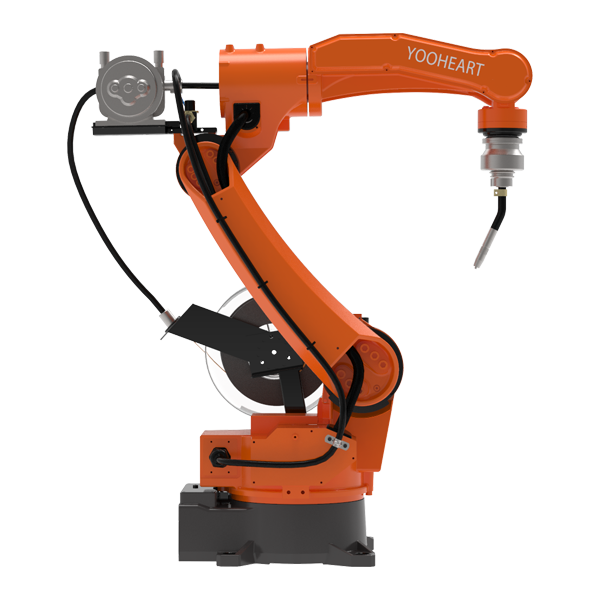

Robot synergy with one axis positioner

In this Picture, our customer use 2000mm reach robot connect two 1 axis positioner

Robot will keep on welding when workers load work piece at one positioner.

In this way, reduce cost and raise productivity.

FIGURE 2

Introduction

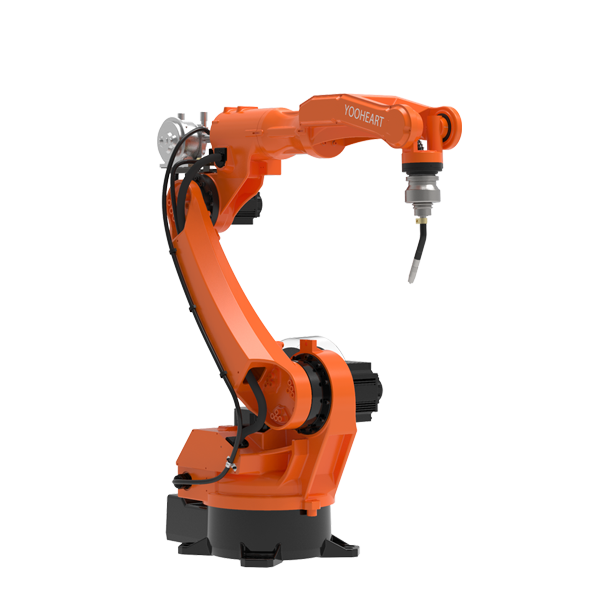

2000mm arm length Robot

Right picture shows our 2meter reach robot welding animal fence.

work piece is square pipe, Customer use Aotai 350A welder with low spatters function.

FIGURE 3

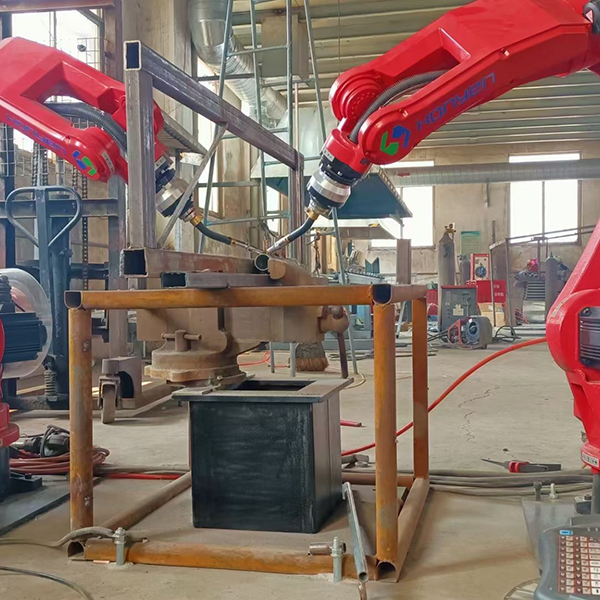

Introduction

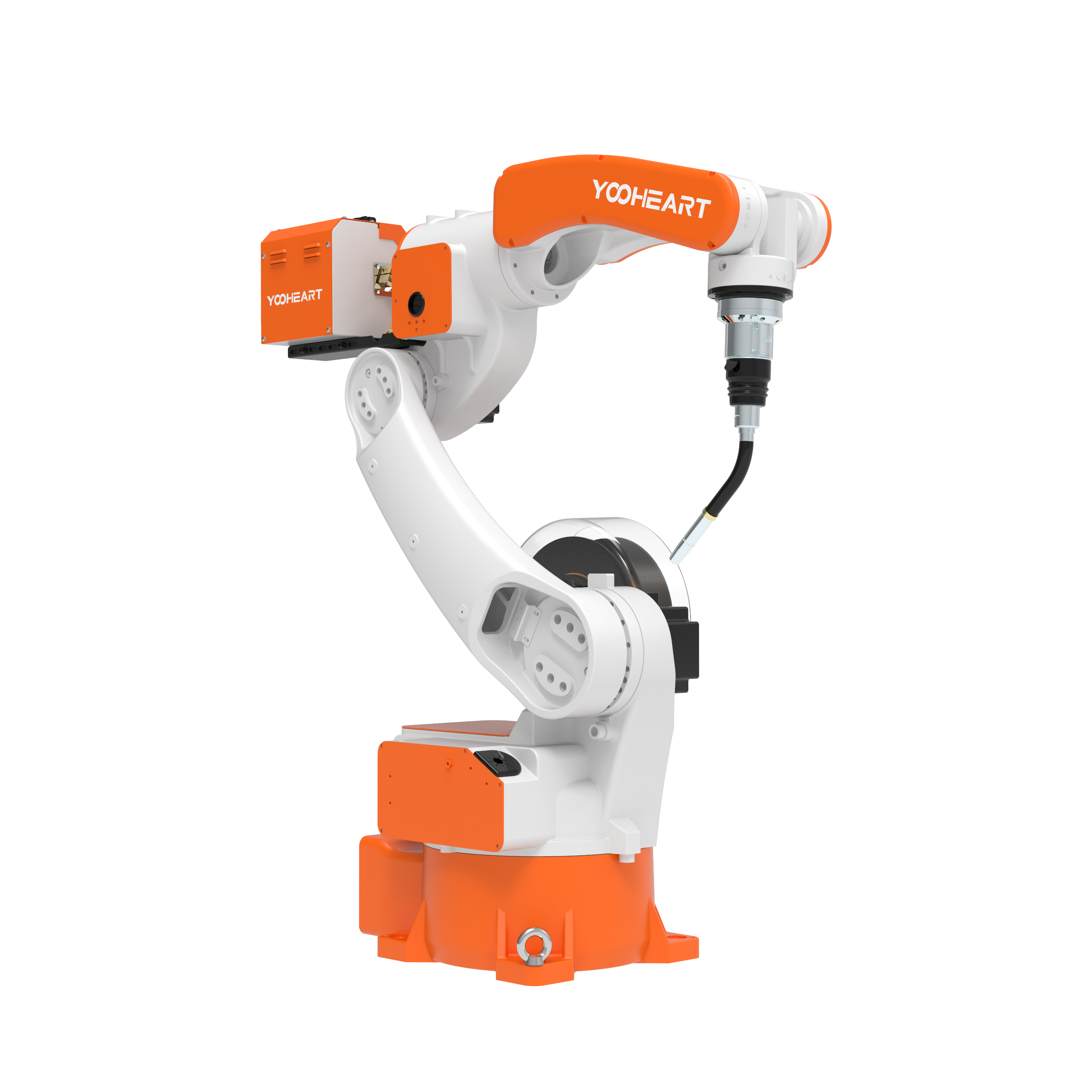

Two robot working together

Left pictures show two Yooheart robot synergy together.

In order to raise welding speed, and solve the difficulty of welding position(some times one robot will meet torch position problem), Two welding robot will be installed

DELIVERY AND SHIPMENT

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOOHEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOO HEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in YOO HEART factory. There will be a wechat group or whatsapp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc. will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.How many external axis can YOO HEART robot add?

A.At present, YOO HEART robot can add 3 more external axis to robot which can collaborate with robot. That is to say, we have standard robot work station with 7 axis, 8 axis and 9 axis.

Q2. If we want to add more axis to the robot, is there any choice?

A. Do you know PLC? If you know this, our robot can communicate with PLC, and then give signals to PLC to control external axis. In this way, you can add 10 or more external axis. The only shortage of this way is that the external axis can’t collaborate with robot.

Q3. How PLC communicate with robot?

A. We have i/O board in the control cabinet, there are 22 output port and 22 input port, PLC will connect I/O board and receive signals from robot.

Q4. Can we add more I/o port?

A. For simply weld application, these I/O port is enough, if you need more, we have I/O expanding board. You can add another 22 input and output.

Q5. What kind of PLC do you use?

A. Now we can connect Mitsubishi and Siemens and also some other brands.